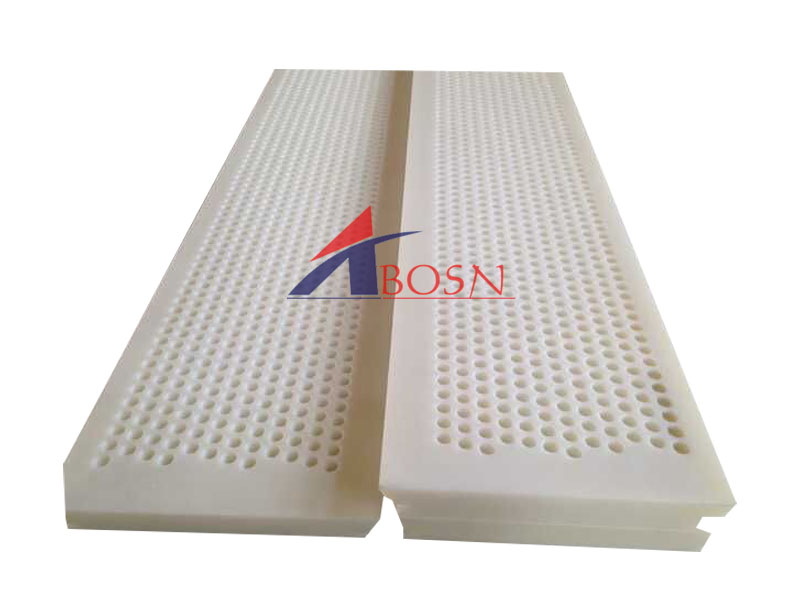

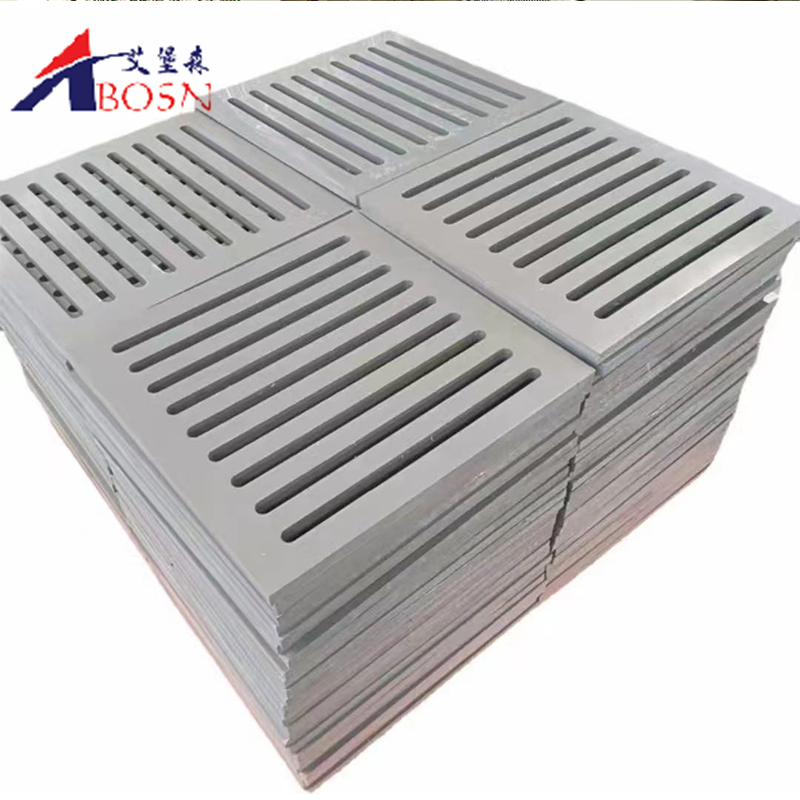

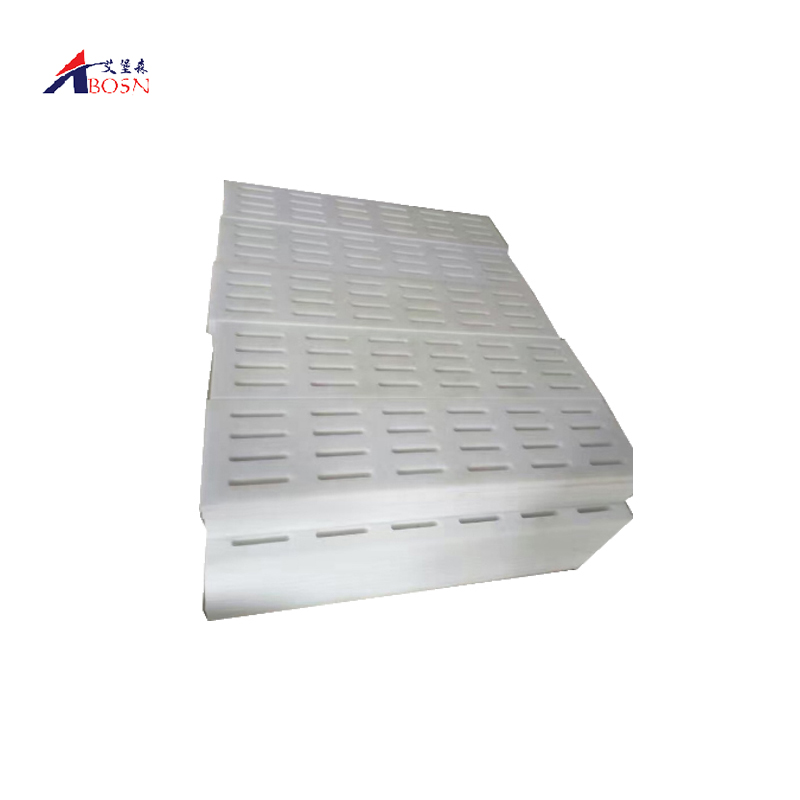

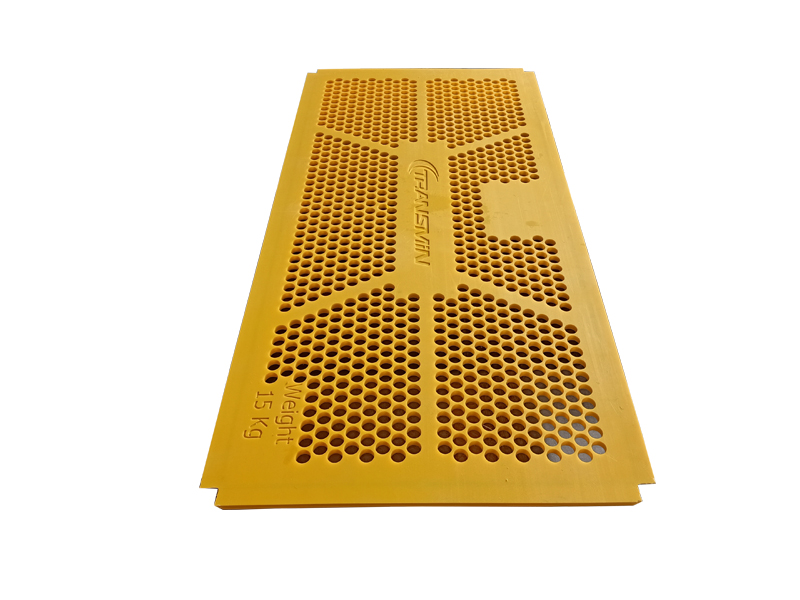

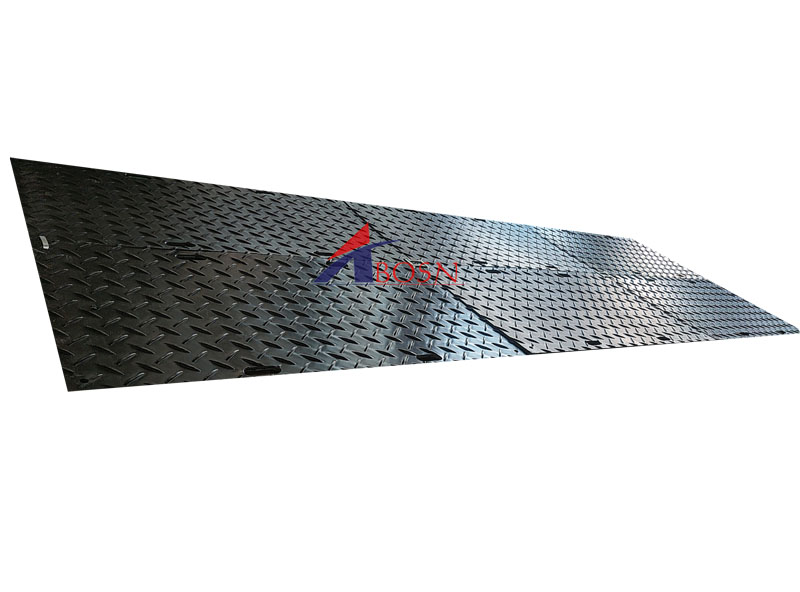

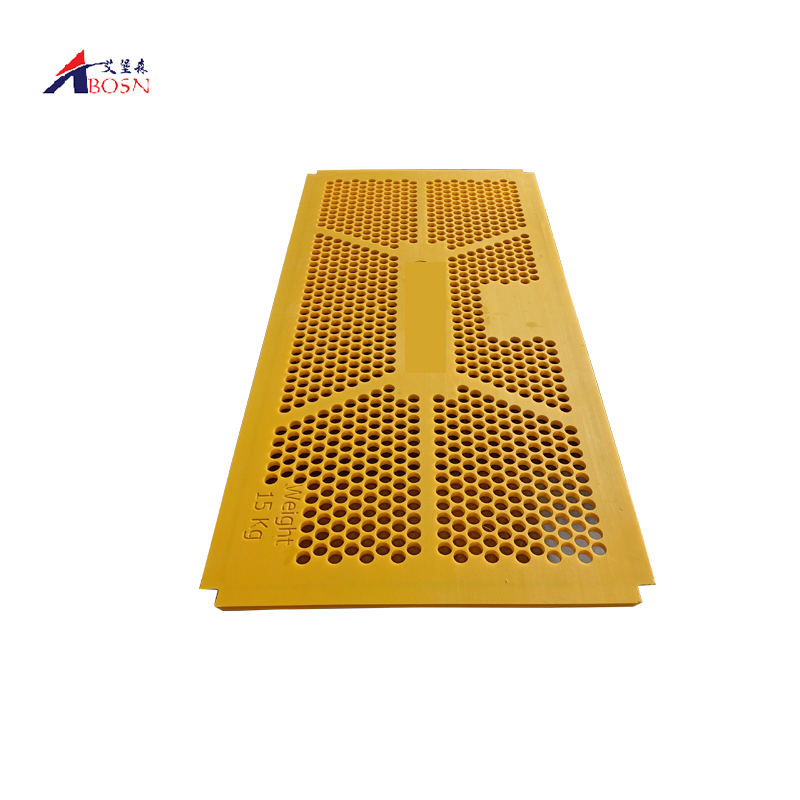

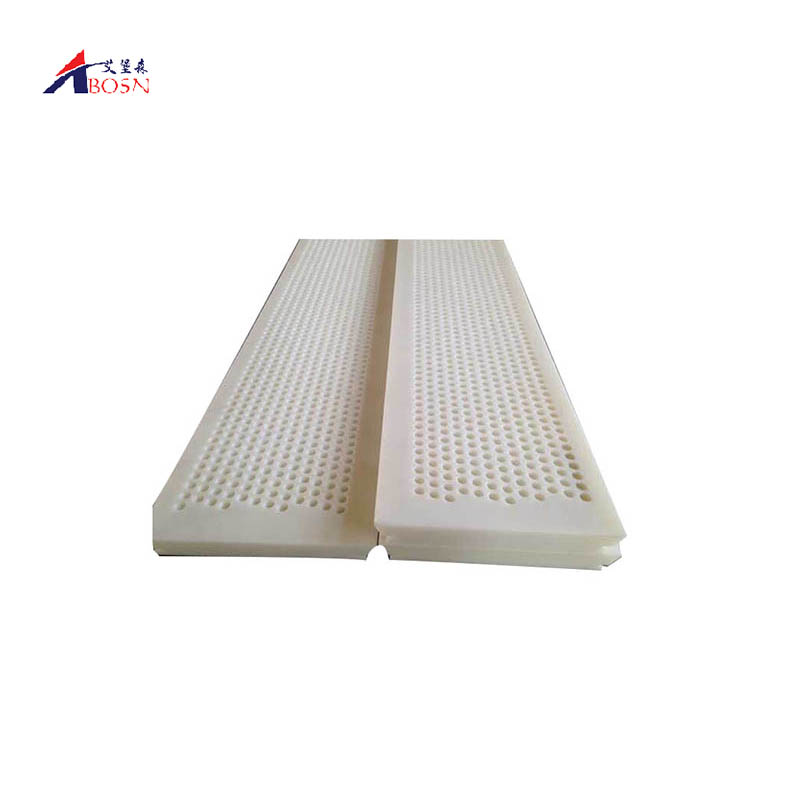

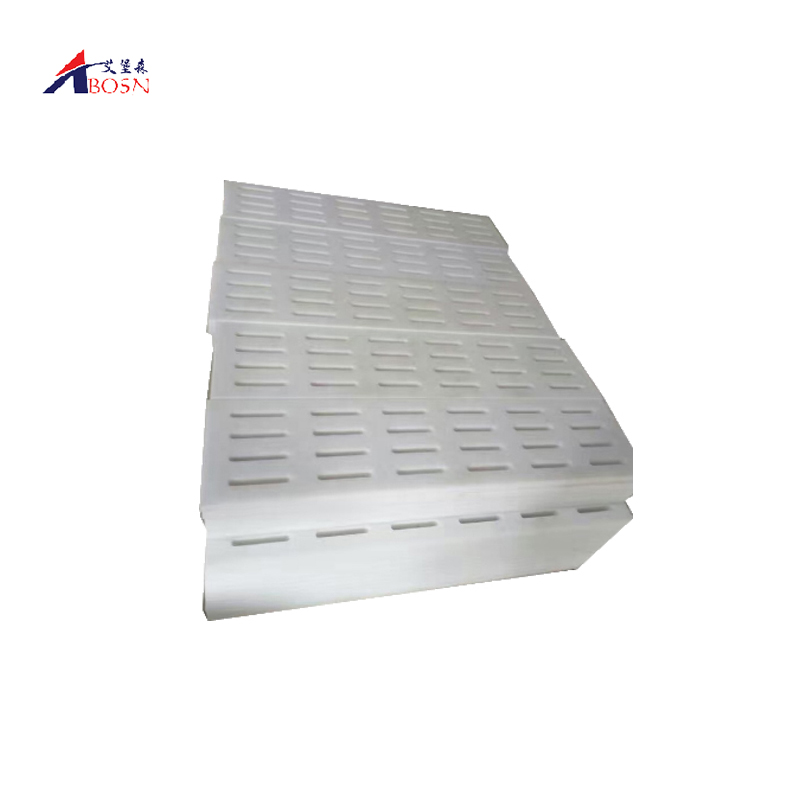

Many years of international experience made uhmwpe a specialist material for dewatering elements in the paper industry. Extensive research and development work in laboratories creates permanently new compounds to meet the steadily increasing requirements of modern paper machines. Many of the compounds are patented. New production technologies enables us to fabricate dewatering elements up to 10m lengths.

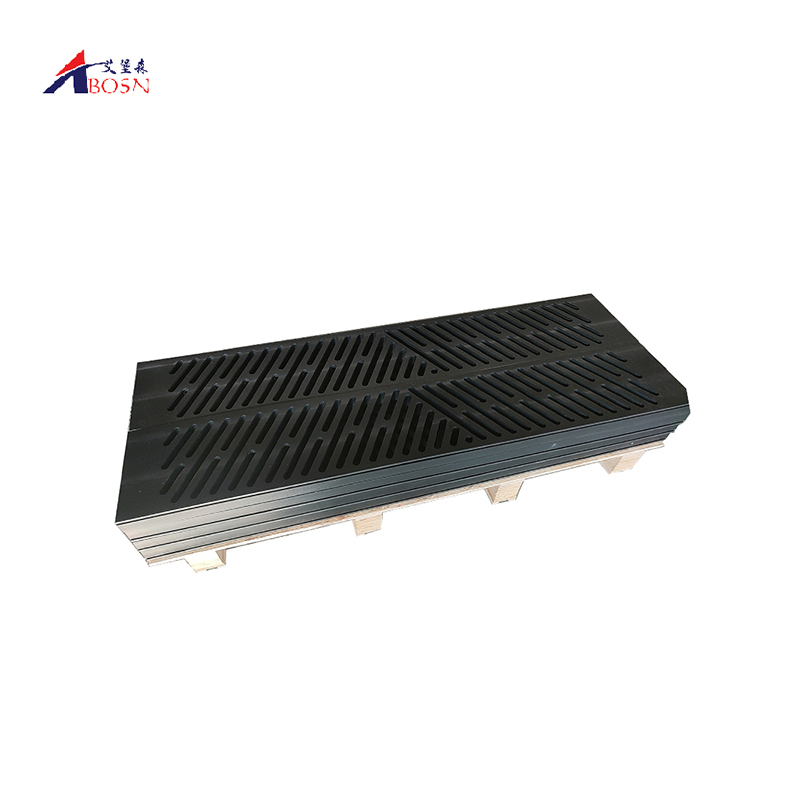

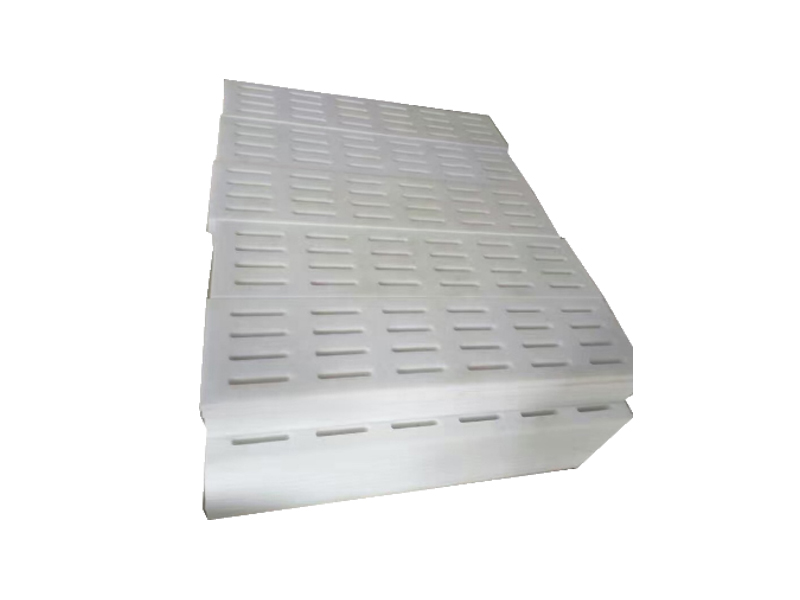

The lifetimes of fabrics and dewatering elements depend to a large extent upon the gliding of the plastic used. UHMWPE has an extremely low coefficient of friction. By using gliding additives the coefficient of friction of uhmwpe is further reduced.

This cause good functioning properties of the fabrics even in connection with the covers and blades, which are installed in the much drier portion at the wet end section. The non-porous, waxy surface of uhmwpe prevents build up of fibres and other components.

UHMWPE is a thermoplastic material developed for the use in extreme conditions. Due to uhmwpe's high molecular weight it is extremely wear resistant. It exhibits excellent sliding properties because of its homogeneous and waxy surface. Therefore UHMWPE is most suitable for dewatering elements in paper machines. These specially developed material grades have been successfully used by both manufacturers of paper machines and paper mills in more than 40 countries.

Contact us

E-mail:fiona@dzabosn.com

Whatsapp:+86 175 5341 8926

Phone:+86 175 5341 8926