UHMWPE fender pad

The introduction of Ultra-High Molecular Weight Polyethylene (UHMWPE) fender pads marks a significant leap forward in enhancing safety and efficiency across global ports and docks. These innovative pads, manufactured by leading companies such as Abosn, have quickly become the material of choice for marine infrastructure due to their unparalleled combination of strength, durability, and low maintenance.

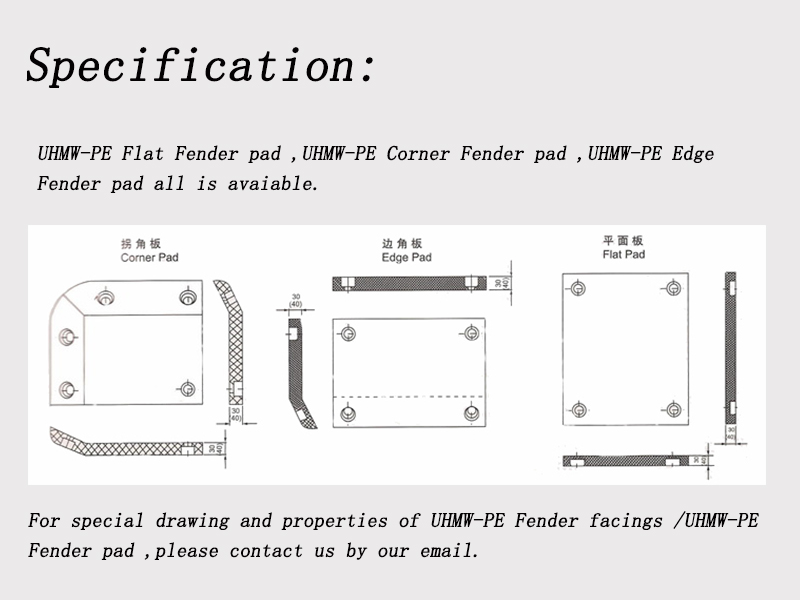

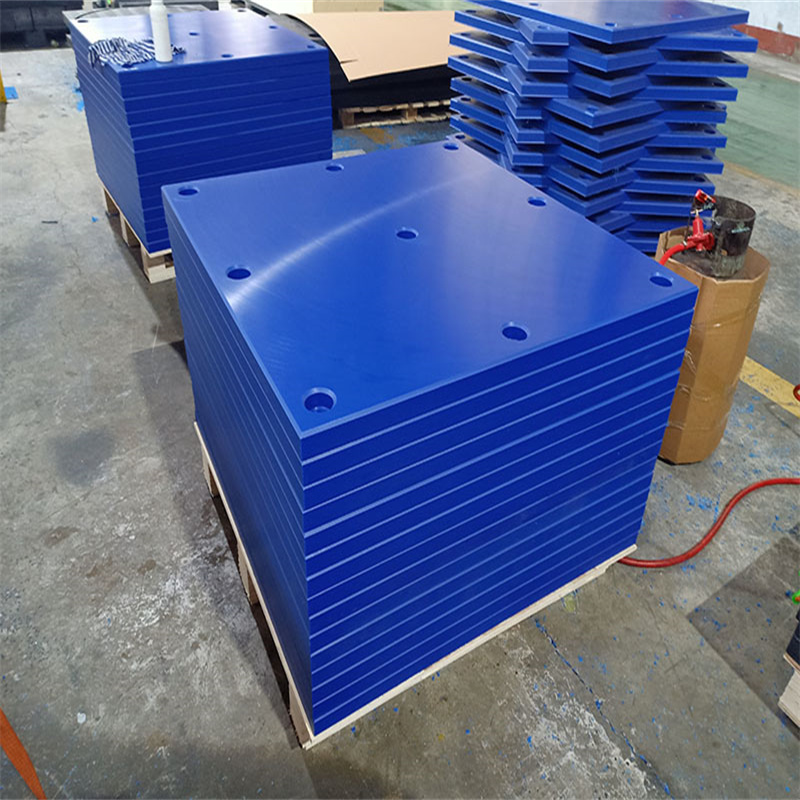

ABOSN offer UHMWPE fender pads in various sizes, shapes, and colors to meet specific customer needs. These companies also provide specialized formulations, such as anti-UV and fire-resistant grades, to address unique operational challenges. The ability to customize these pads ensures that they can be tailored to fit any marine environment, from small harbors to large commercial ports.

UHMWPE fender pads feature:

Low Water Absorption: Virtually no water absorption ensures that the pads maintain their integrity and performance over time, even in marine environments.

Non-Toxicity and Odorlessness: Meeting FDA and USDA standards, these pads are safe for use in environments where environmental and health concerns are paramount.

Self-Lubrication: Similar to PTFE, this property reduces wear and tear, extending the lifespan of the fender pads.

Corrosion Resistance: UHMWPE's chemical stability means it can withstand the corrosive effects of seawater, salt, and other chemicals, ensuring long-term durability.

Anti-Bacterial Properties: These pads resist microbial growth, further contributing to a safer and cleaner marine environment.

Low Coefficient of Friction: Facilitating smoother vessel movement, reducing the risk of damage during docking and undocking operations.

Impact and Abrasion Resistance: Providing superior protection against the forces encountered during ship-to-dock interactions.

Resistance to Weathering and Aging: Maintaining their properties and appearance even under prolonged exposure to sunlight and harsh weather conditions.

High Tensile Strength: Offering exceptional strength and resilience, crucial for withstanding the dynamic forces in marine settings.

UHMWPE fender pads application:

Dock and Wharf Protection: Serving as a critical barrier between vessels and docking structures, preventing damage and ensuring smooth berthing.

Pontoon and Pile Guide Bearings: Guiding vessels into position with minimal resistance.

Lifeboat Slipways: Ensuring safe and easy launching and recovery of lifeboats.

Fender Panel Facing Pads: Enhancing the protective capabilities of existing fender systems.

Rubbing Strips and Shields: Protecting the sides of jetties and wharves from abrasion and impact.