Understanding UHMWPE Sheets

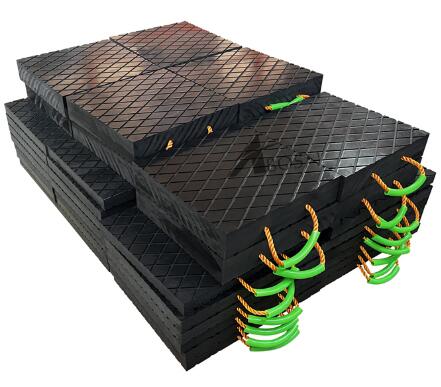

Ultra-high molecular weight polyethylene (UHMWPE) sheets are revolutionizing conveying systems worldwide. Known for their exceptional durability, low friction, and resistance to wear, these sheets are becoming indispensable in industries requiring efficient material handling. But what exactly are UHMWPE sheets, and why are they so effective in this application?

UHMWPE sheets are made from a high-density polymer that offers superior abrasion resistance and longevity compared to traditional materials. Their low coefficient of friction ensures smooth operation, minimizing downtime caused by wear or malfunctions in conveying systems.

Benefits of Using UHMWPE Sheets in Conveying Systems

The application of UHMWPE sheets in conveying systems brings a host of advantages that improve operational efficiency and longevity. These benefits include:

1. Enhanced Durability: UHMWPE sheets withstand high levels of abrasion and impact, making them ideal for heavy-duty environments. Their ability to resist wear and tear significantly reduces the need for frequent replacements.

2. Reduced Friction: The low-friction properties of UHMWPE minimize drag, ensuring seamless material flow. This characteristic helps prevent blockages and reduces energy consumption.

3. Chemical Resistance: These sheets are impervious to most chemicals, allowing them to perform reliably in industries handling corrosive materials.

4. Noise Reduction: By minimizing contact noise, UHMWPE sheets contribute to a quieter, safer work environment.

Applications in Various Industries

UHMWPE sheets find applications across diverse industries due to their versatile properties. In food processing, they help ensure hygienic material transport, while in mining, they offer robust performance in harsh conditions. Other sectors, such as packaging, pharmaceuticals, and automotive manufacturing, also benefit from the unique qualities of these sheets.

The adaptability of UHMWPE sheets makes them a preferred choice for conveying systems that demand high efficiency and reliability.

Installing and Maintaining UHMWPE Sheets

Proper installation and maintenance are crucial to optimizing the performance of UHMWPE sheets in conveying systems. During installation, it is essential to ensure that the sheets are correctly aligned and securely fastened to avoid misalignments and potential system failures.

Regular maintenance, including inspections for wear and cleaning, will prolong the lifespan of the sheets. Fortunately, the inherent properties of UHMWPE make maintenance straightforward, as the material resists dirt accumulation and corrosion.

Environmental Impact and Sustainability

UHMWPE sheets are not only effective but also contribute to sustainability. Their long lifespan reduces the frequency of replacements, minimizing waste. Additionally, their chemical inertness ensures they do not leach harmful substances, making them an environmentally responsible choice for conveying systems.

Industries seeking sustainable practices can rely on UHMWPE sheets to meet both performance and environmental goals.

Conclusion

UHMWPE sheets have become a cornerstone of efficient, durable, and sustainable conveying systems. Their unparalleled performance characteristics and versatility across industries make them a smart investment for businesses looking to enhance operational efficiency.

If you are considering upgrading your conveying systems, consult a trusted supplier of UHMWPE sheets to ensure you get the best quality product for your needs. For additional information or inquiries, contact us to discuss how UHMWPE sheets can transform your material handling processes.