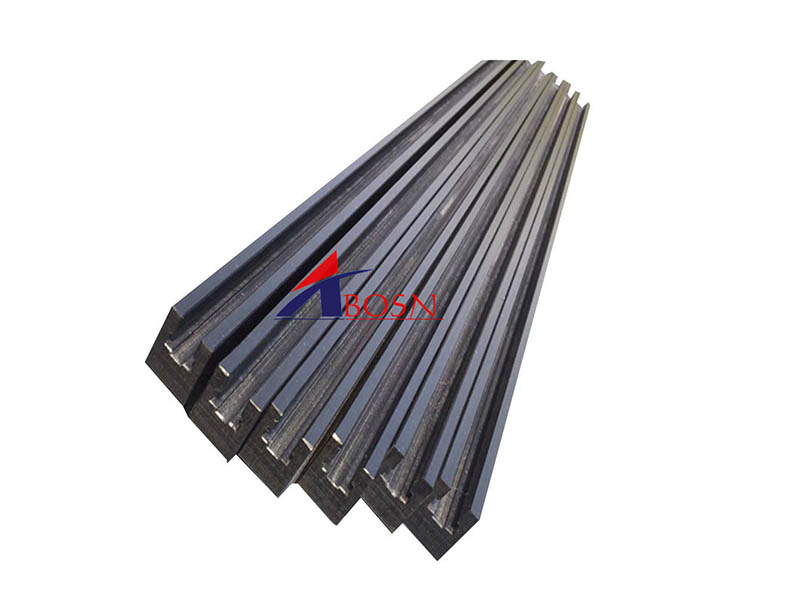

Ultra High Molecular Weight Polyethylene(PE-UHMW) occupies the extreme end of the polyethylene performance spectrum.

With a molecular weight ranging from 3 to 7 million g/mol, PE-UHMW linear polymer chains are 10 times longer than conventional

High Density Polyethylene(HDPE).

The characteristics of the UHMWPE:

1: Little wear.

2: The friction resistance is small.

3; Self-lubrication. (No lubricating oil is needed)

4: It has impact resistance.

5: Operating temperature range -200~+80ºC.

6: Has a shock absorption effect.

7: It is not easy to be damp in a humid environment.

8: It has high chemical resistance.

9: There is corrosion resistance.

What is UHMWPE used for?

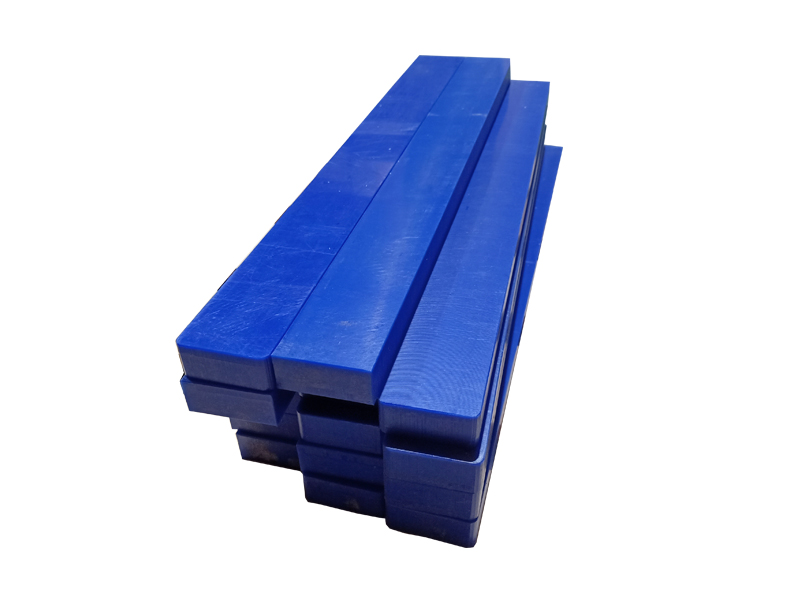

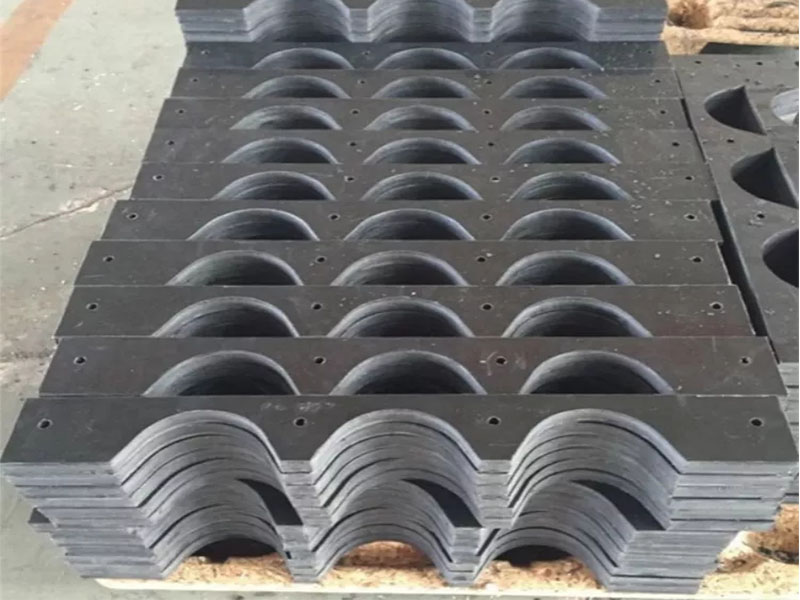

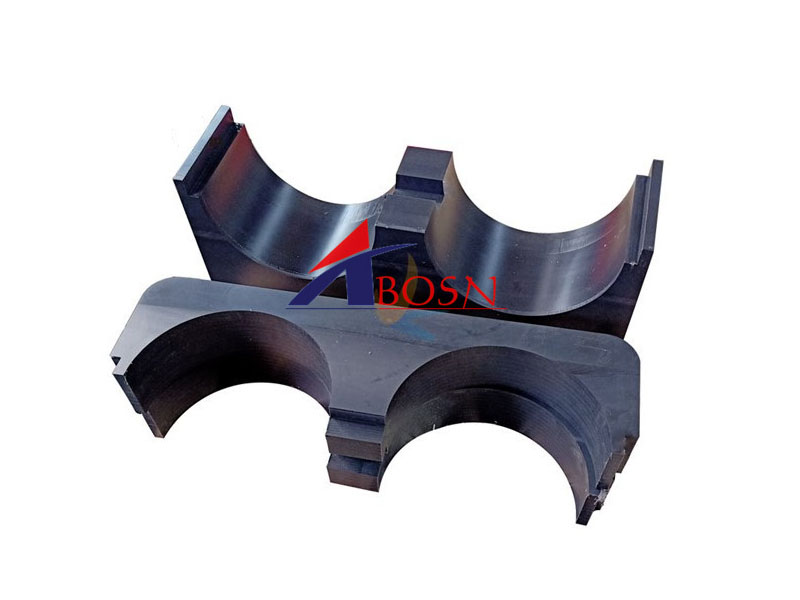

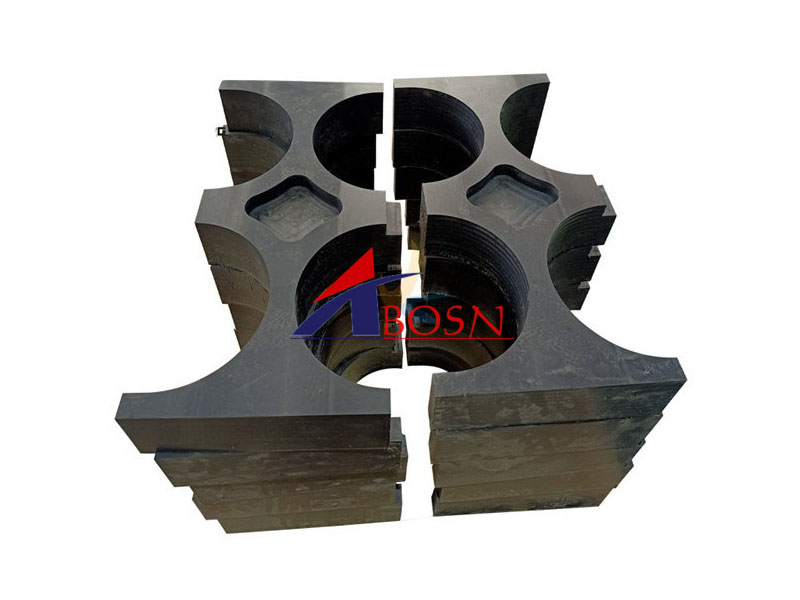

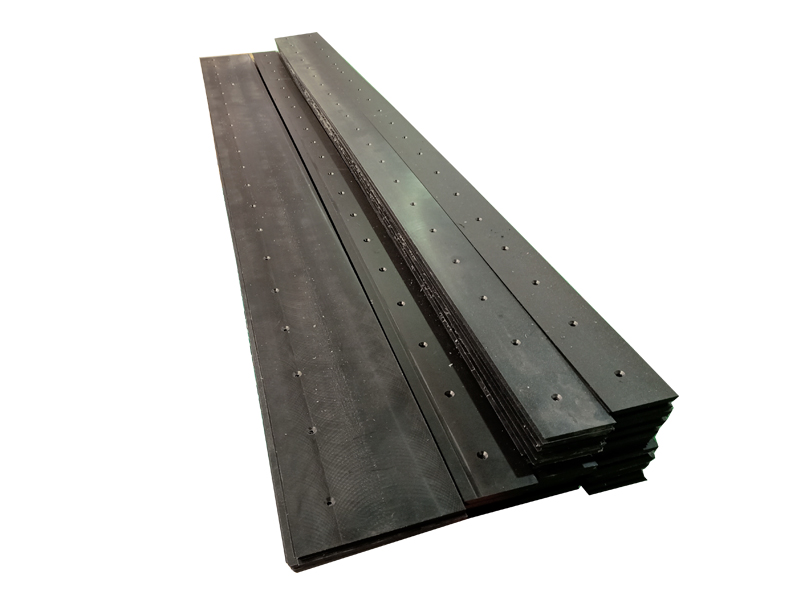

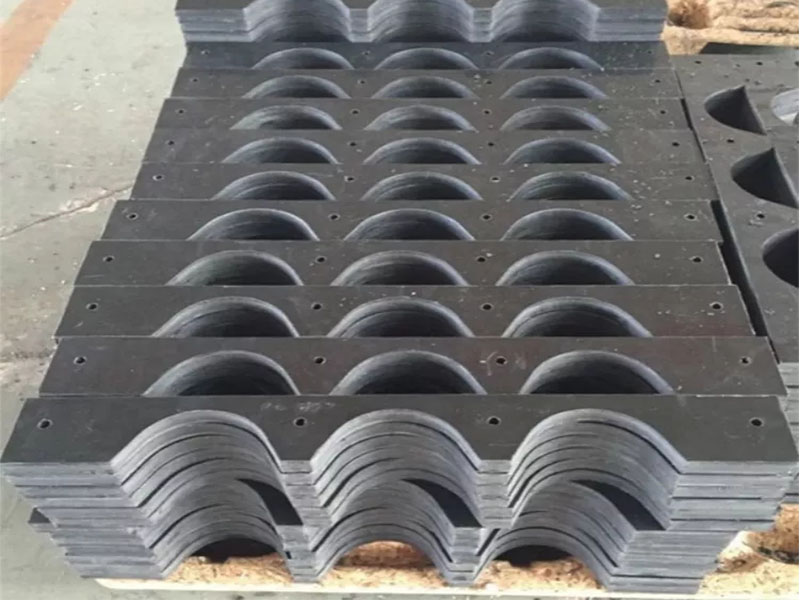

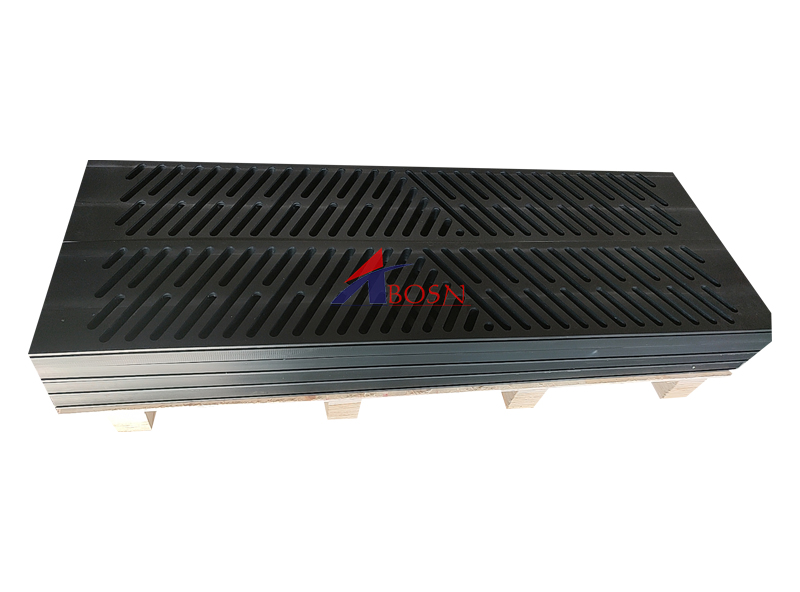

Because UHMWPE has excellent abrasion resistance it is often used for sand, gravel or aggregate process applications.

These environments are incredibly harsh on any bearing material but UHMWPE is one of the few engineering plastics

capable of withstanding such punishing abuse.

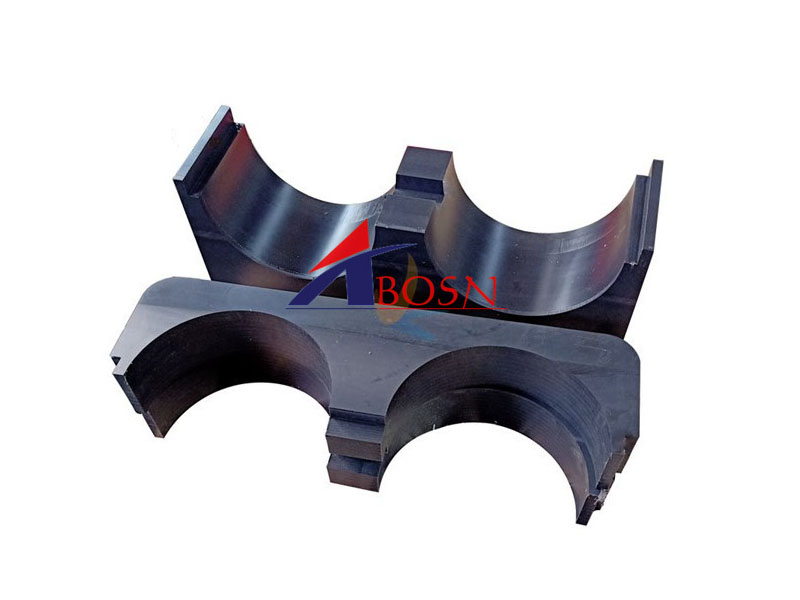

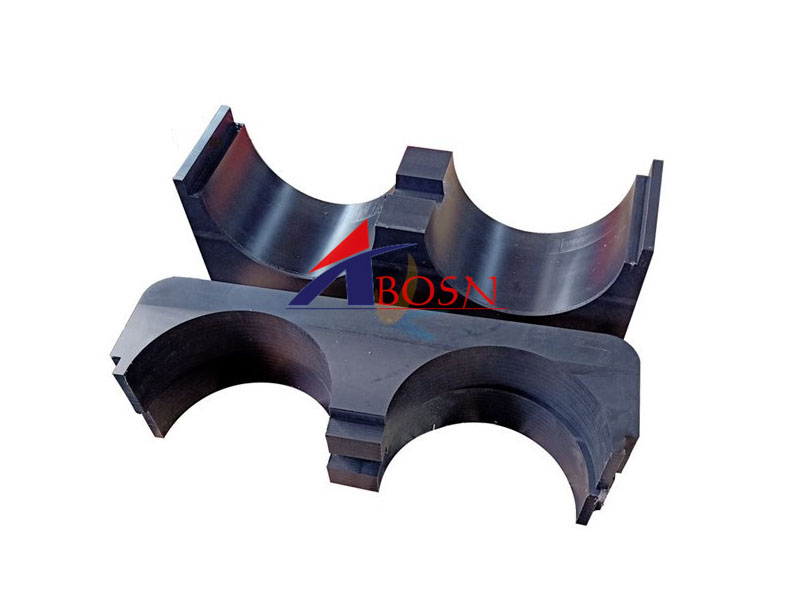

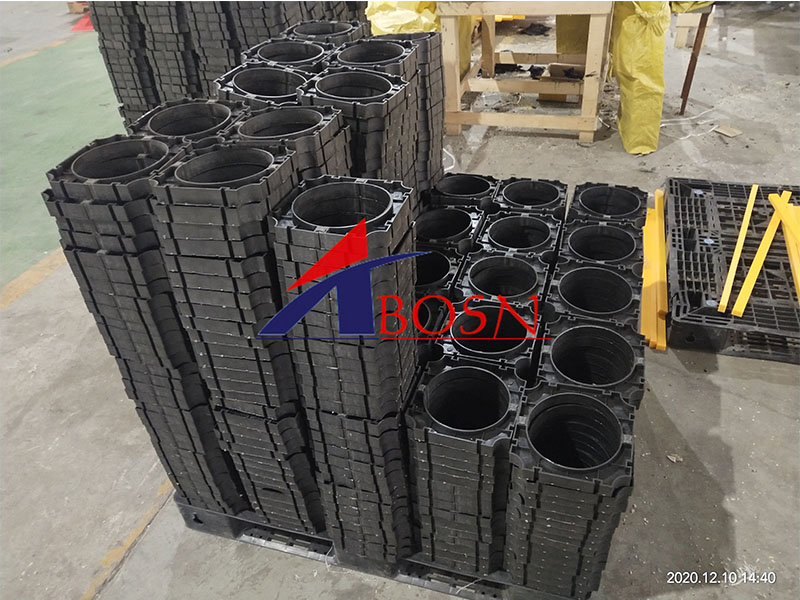

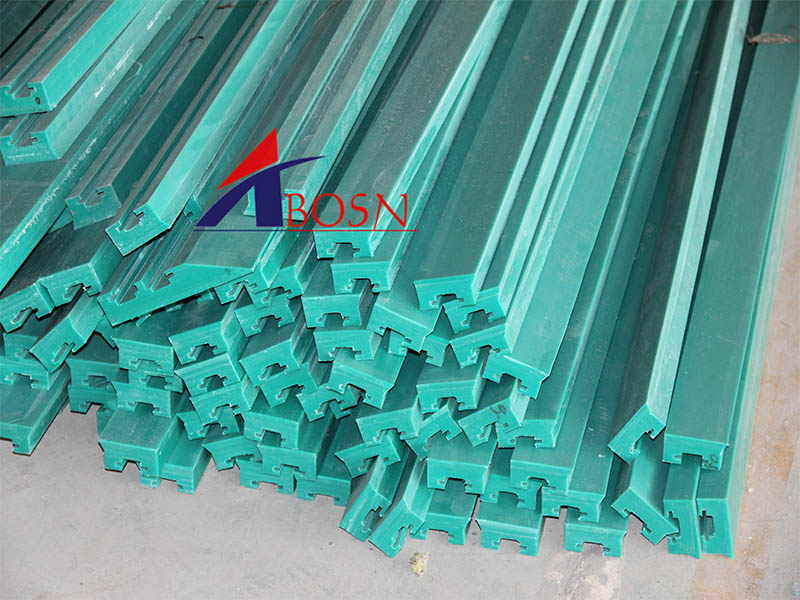

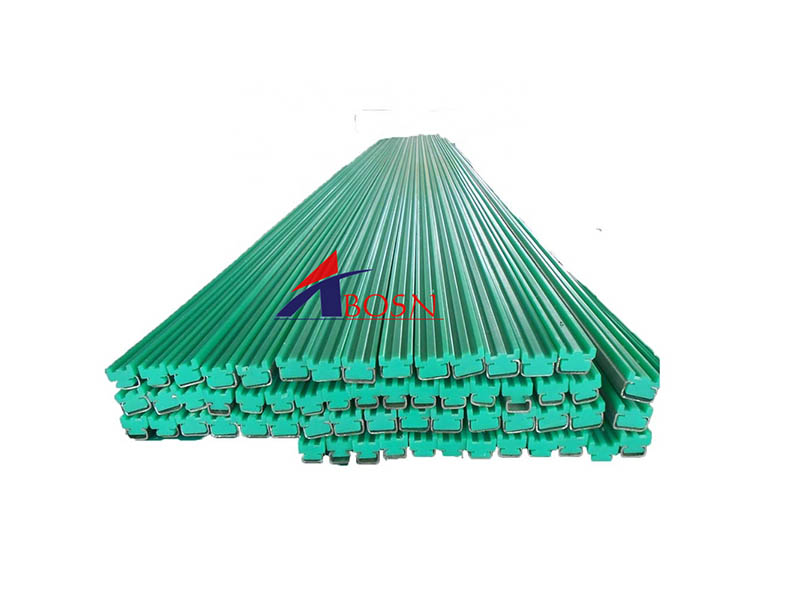

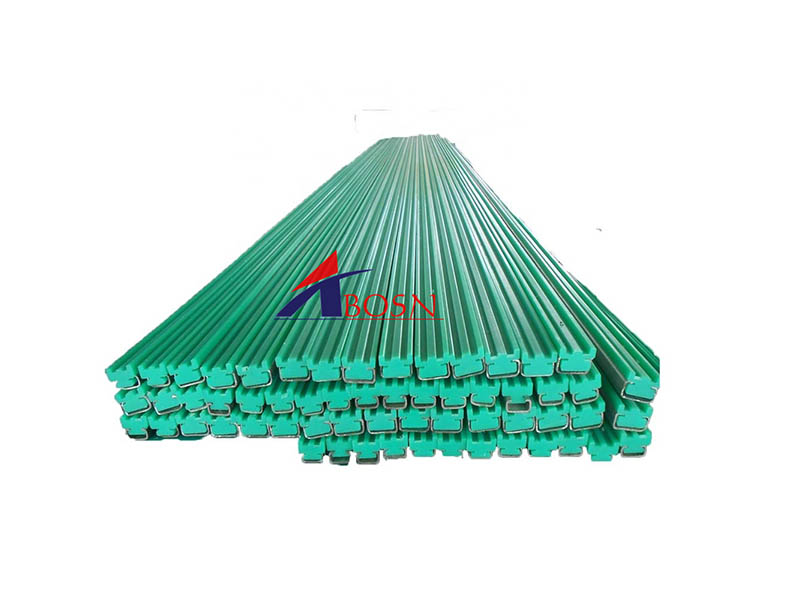

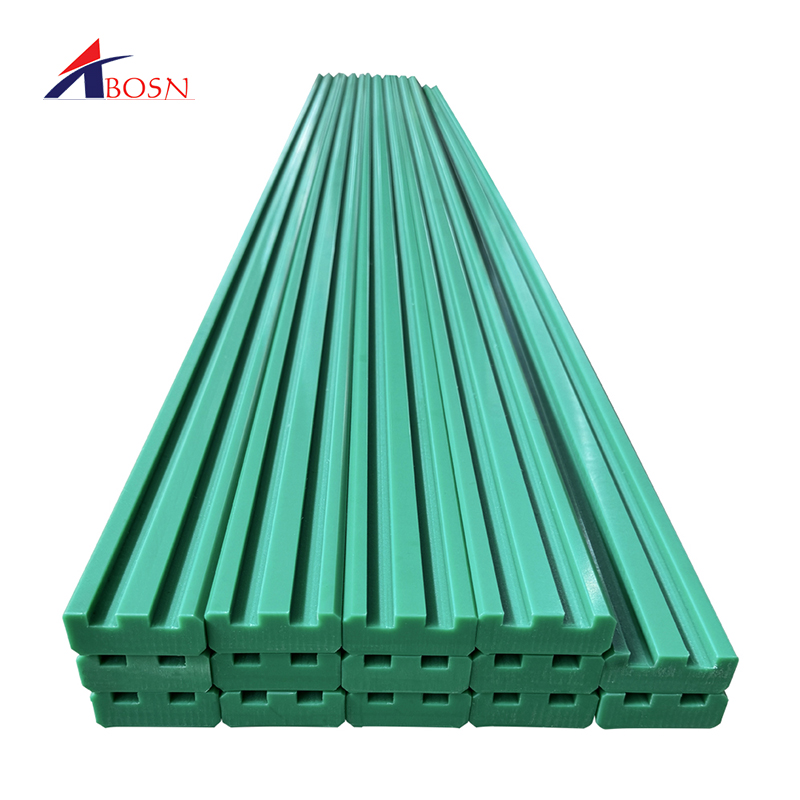

UHMWPE can also be used for low friction pulleys because of its very low co-efficient provides a bearing medium that

is very free running and exceptionally long lasting. It is often found in food production environments where high volumes

of containers need to be guided along conveyors or production lines.

Because it has very low moisture absorption, it is also found in some high demand areas of marine applications.

It's sometimes used in some cryogenic components due to its low operating temperature abilities. Because of its resistance

to wear and impact, UHMWPE continues to find increasing industrial applications, including the automotive and bottling sectors.

Since the 1960s, it has also been the most commonly used material for total joint arthroplasty in orthopaedic and spine implants.

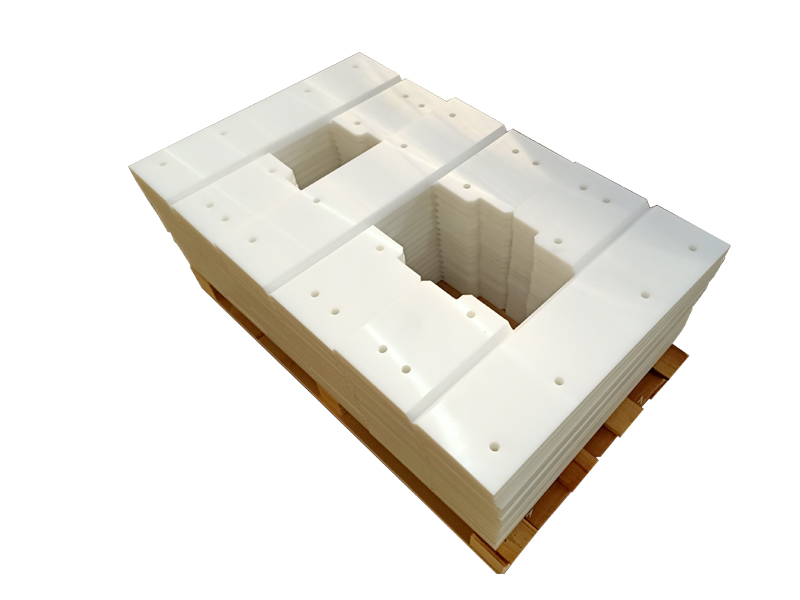

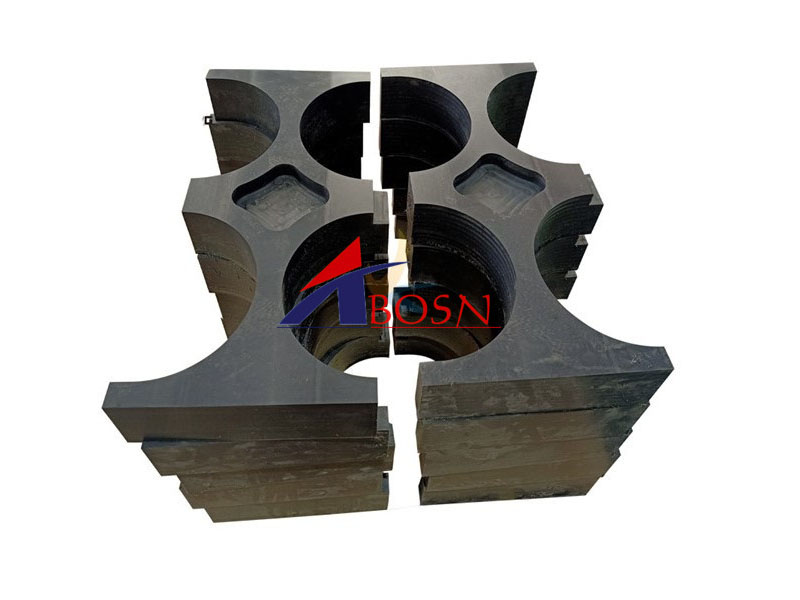

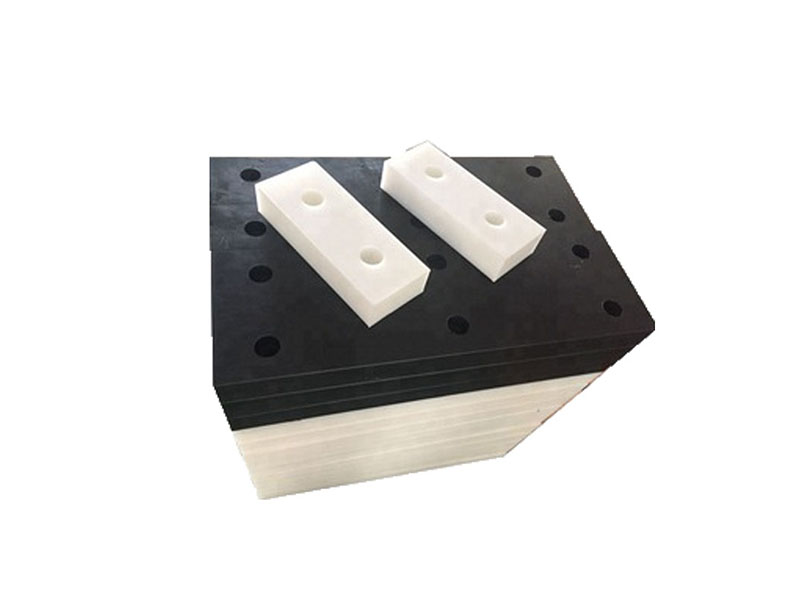

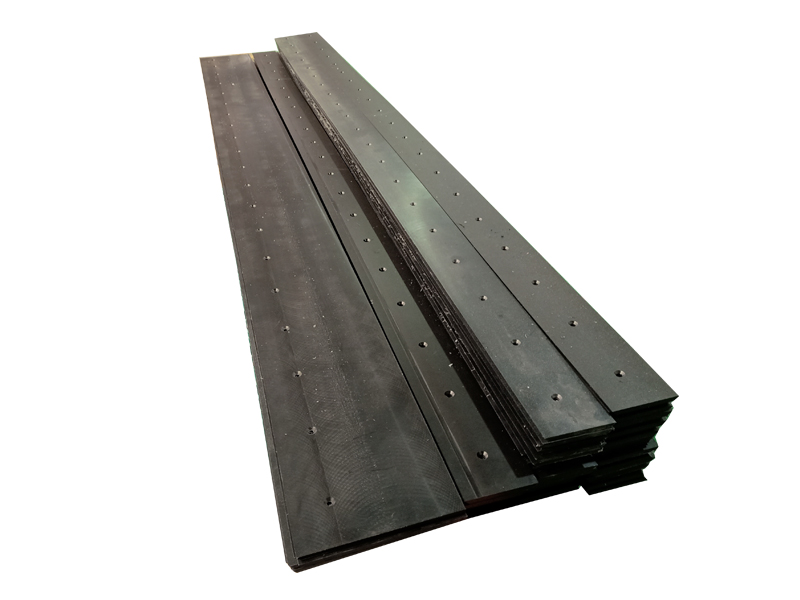

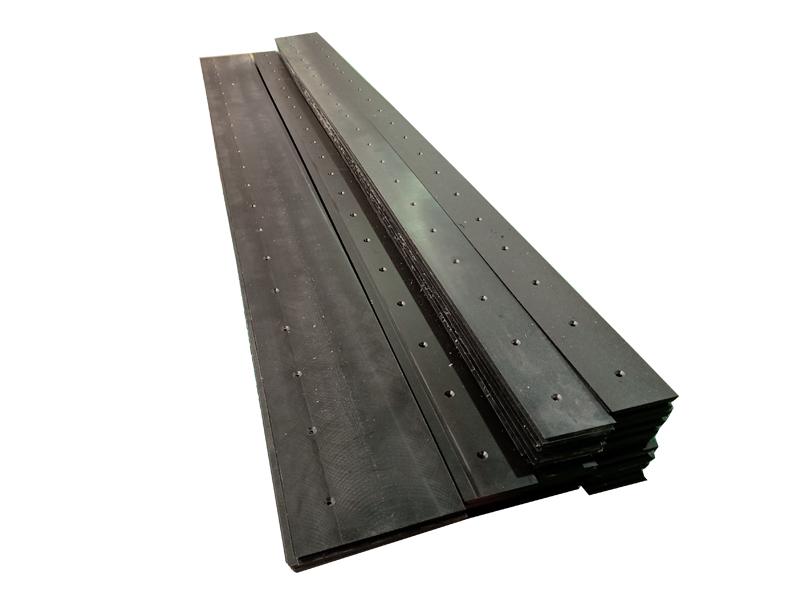

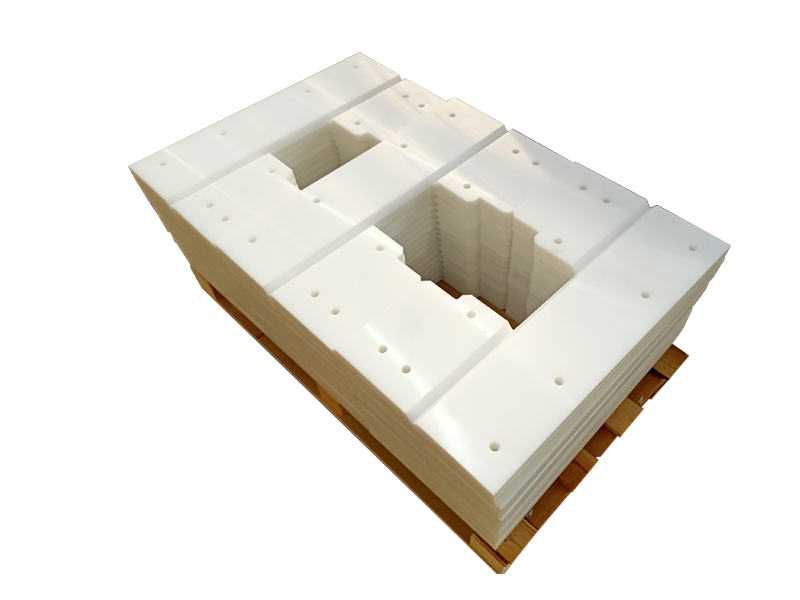

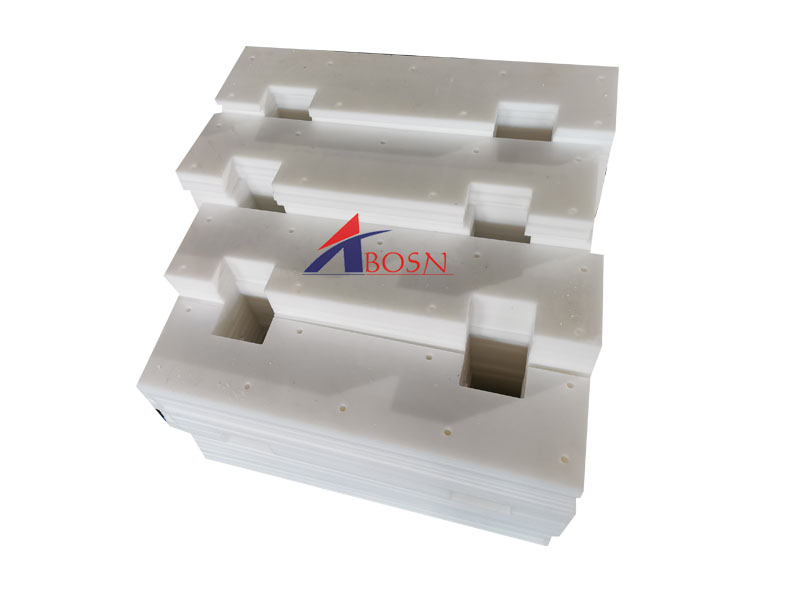

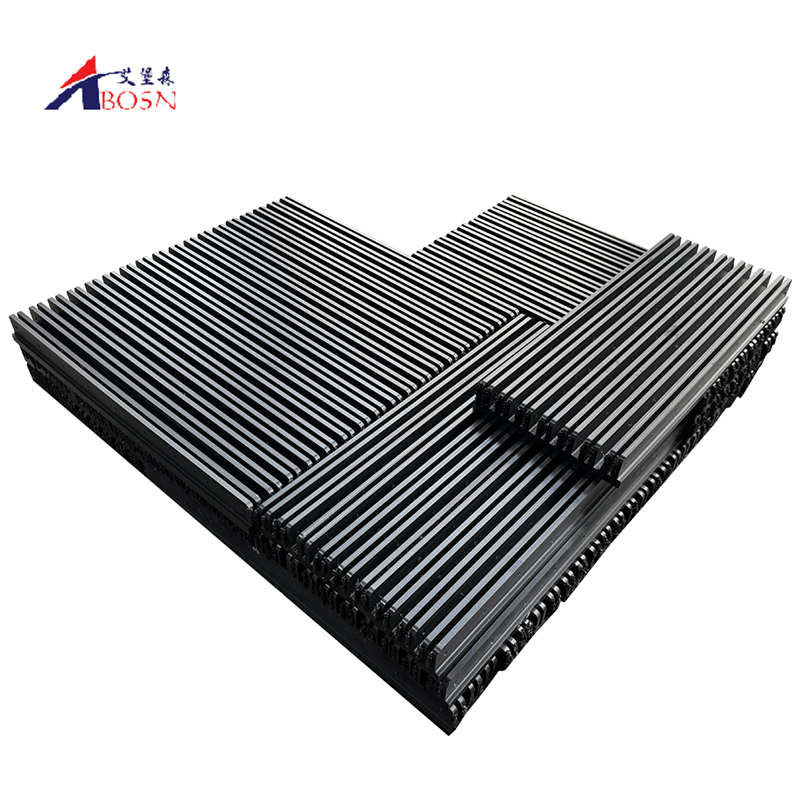

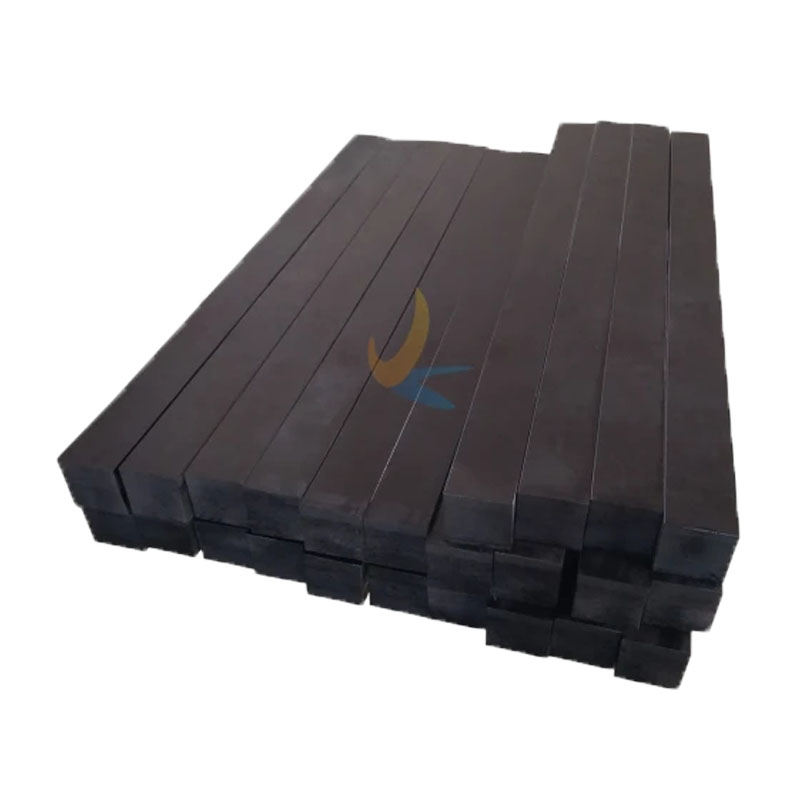

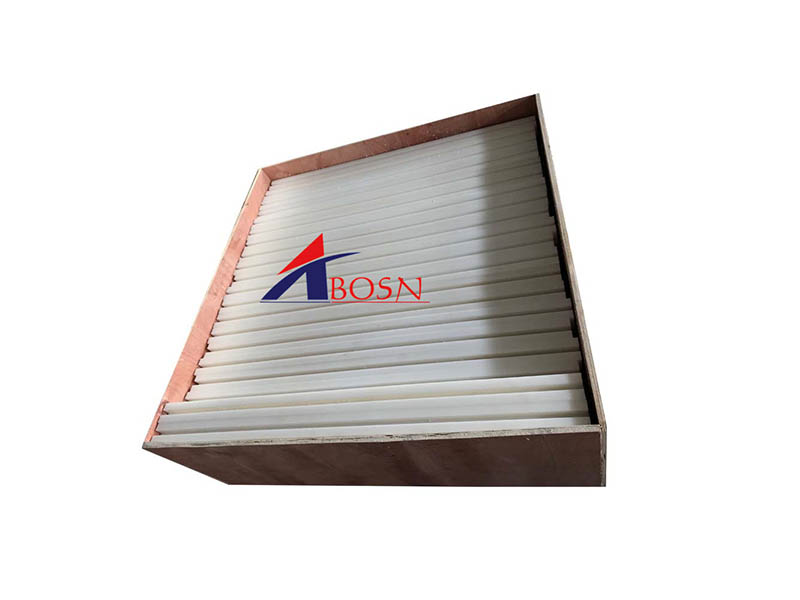

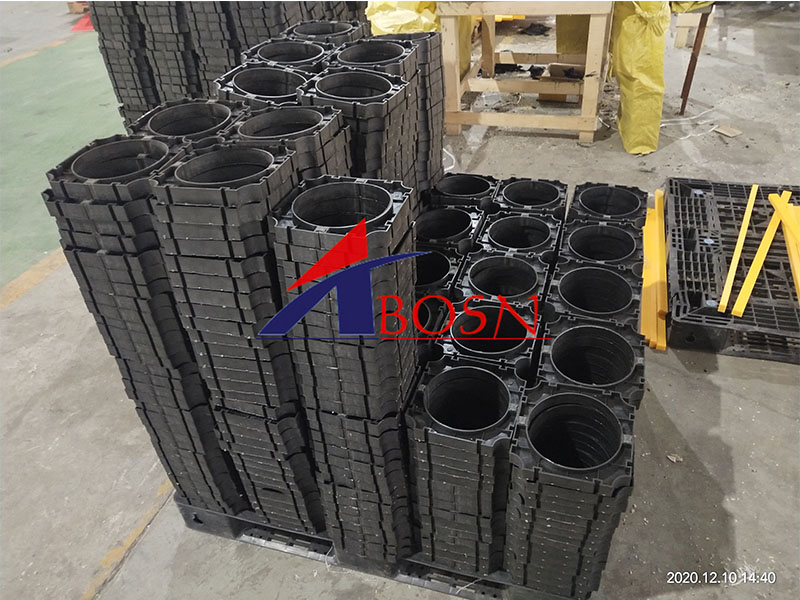

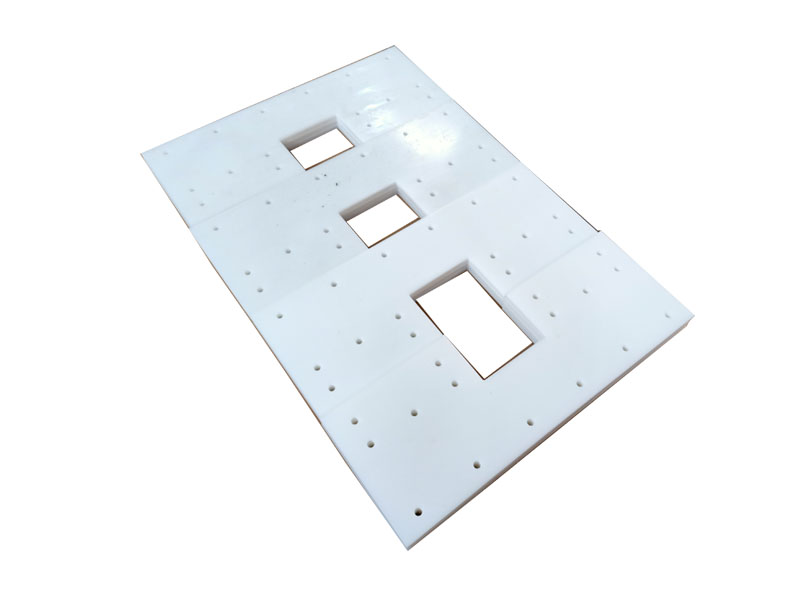

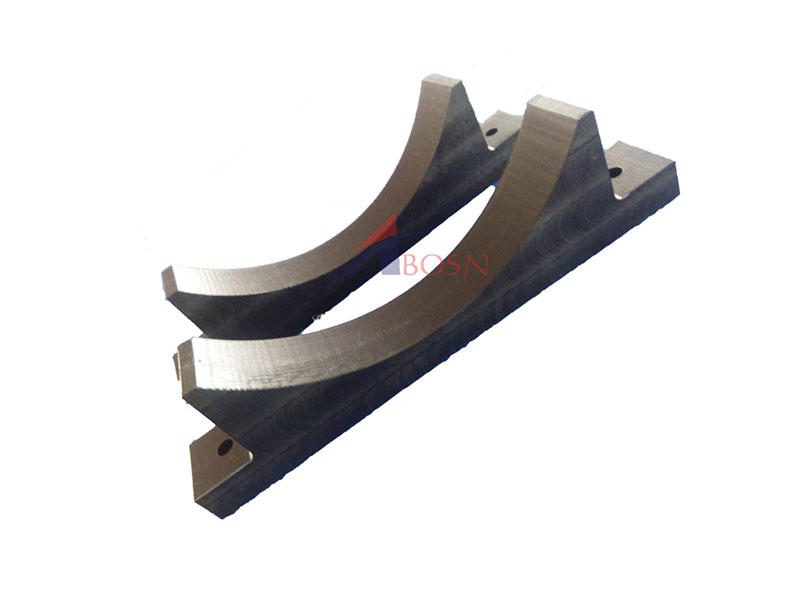

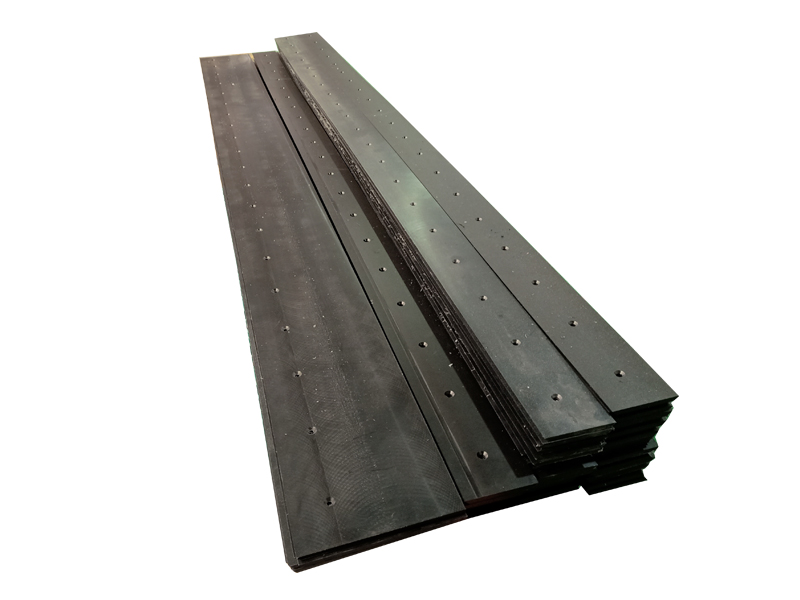

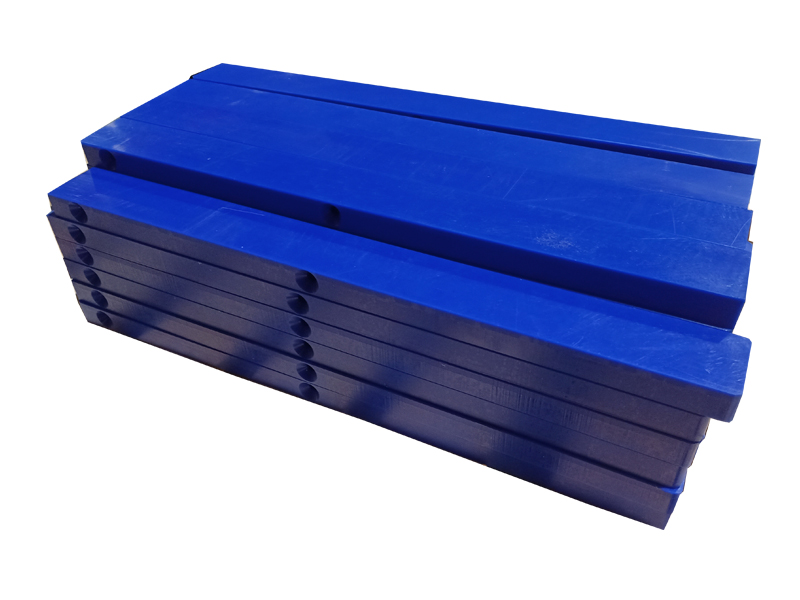

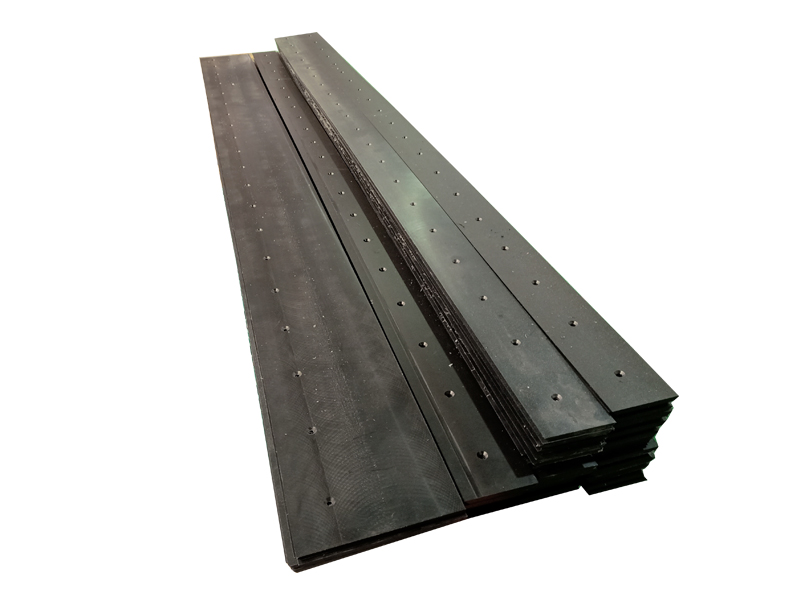

We provide a wide range of UHMW machined parts. Whether your requirements are simple or complex, our experts have the

ability to customized Design and Performance. The outstanding material properties of UHMW-PE allow machined parts to be used

increasingly in the most challenging working conditions.

Pls contact echo@dzabosn.com for more details.