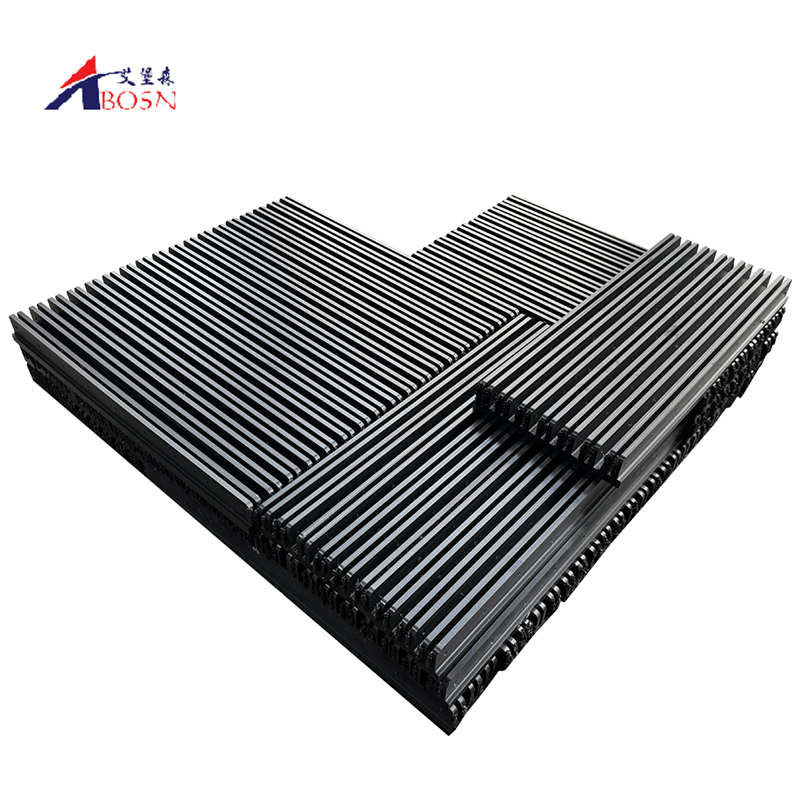

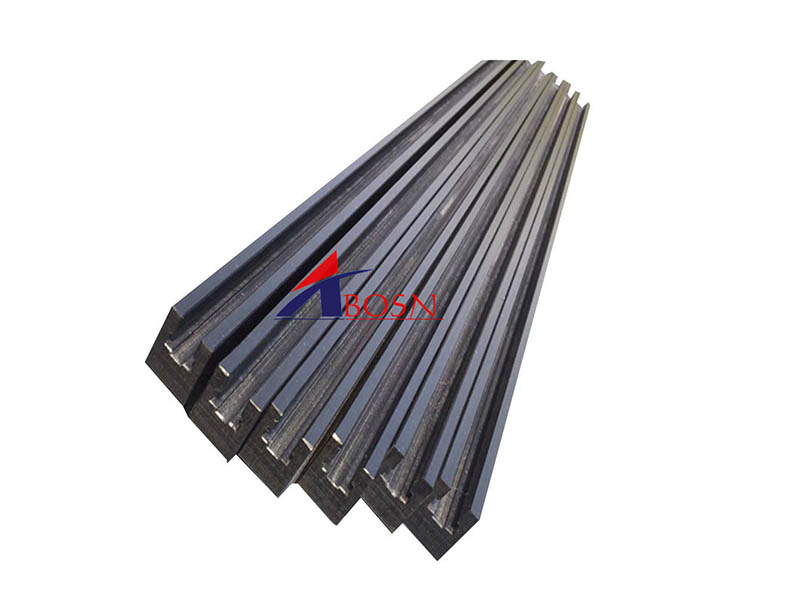

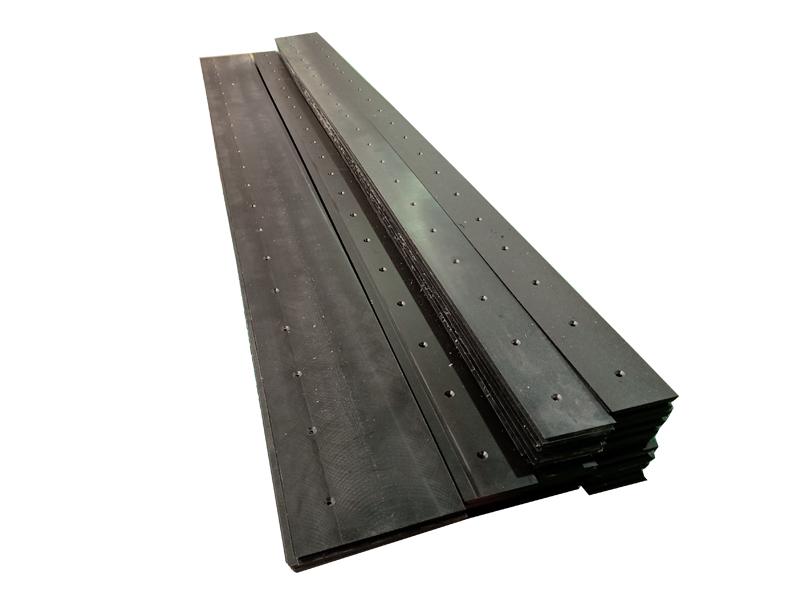

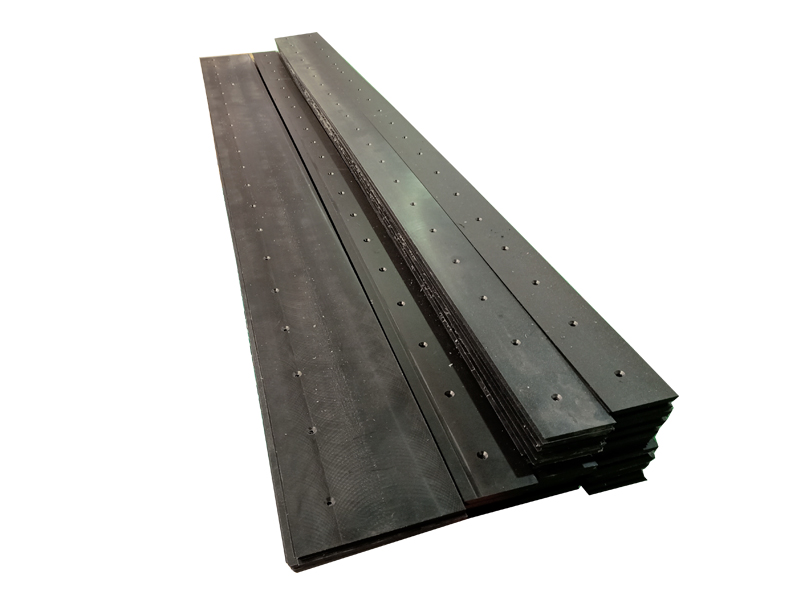

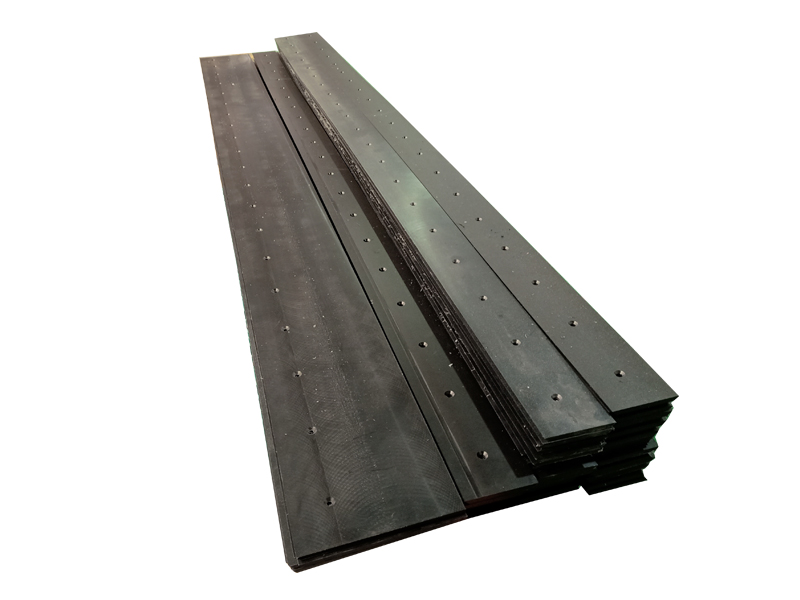

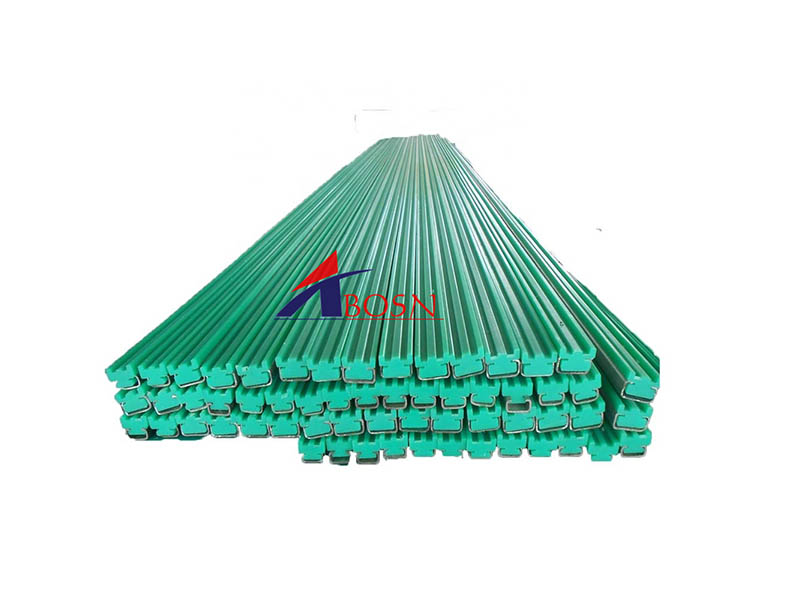

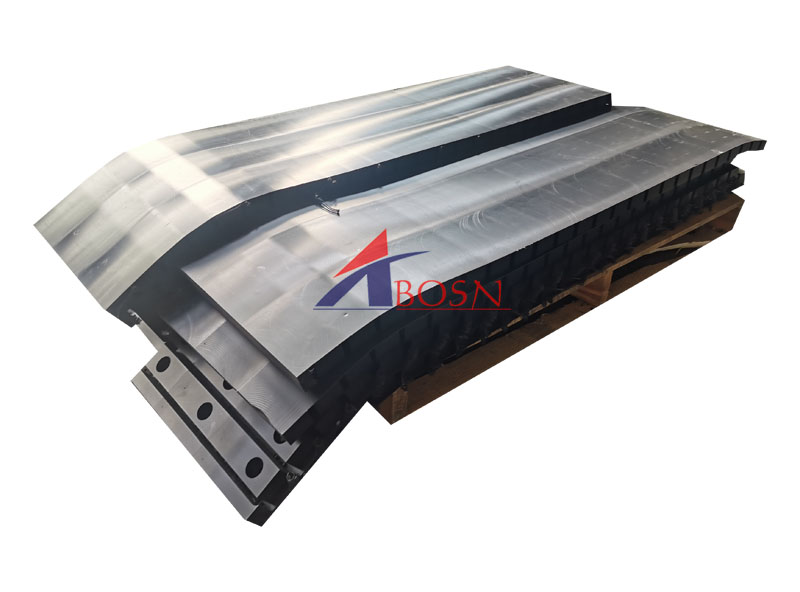

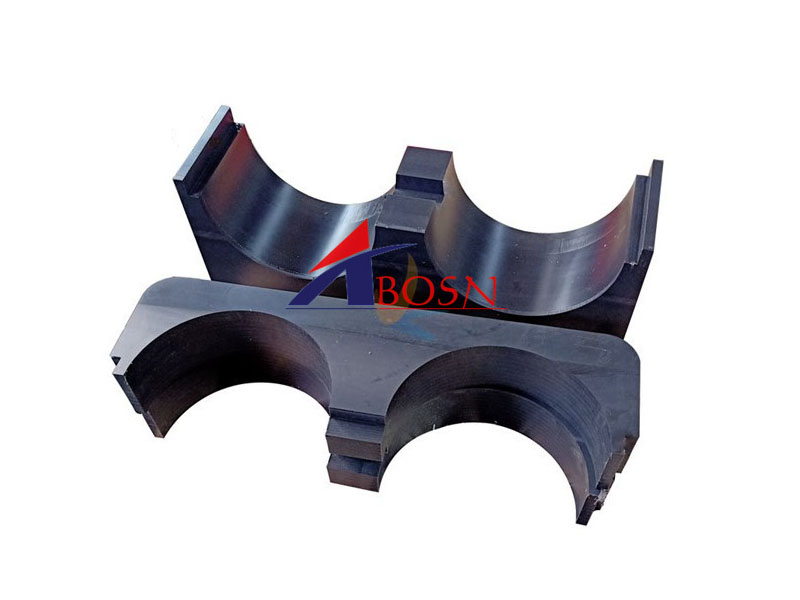

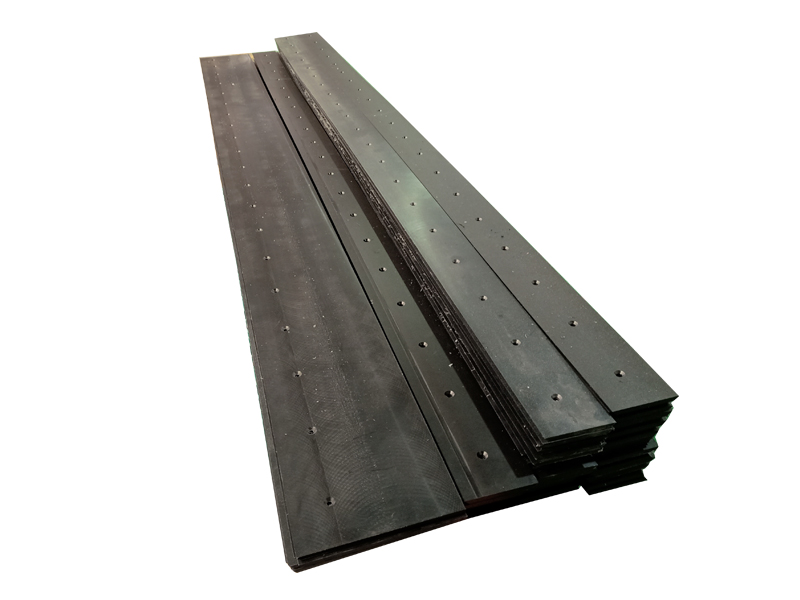

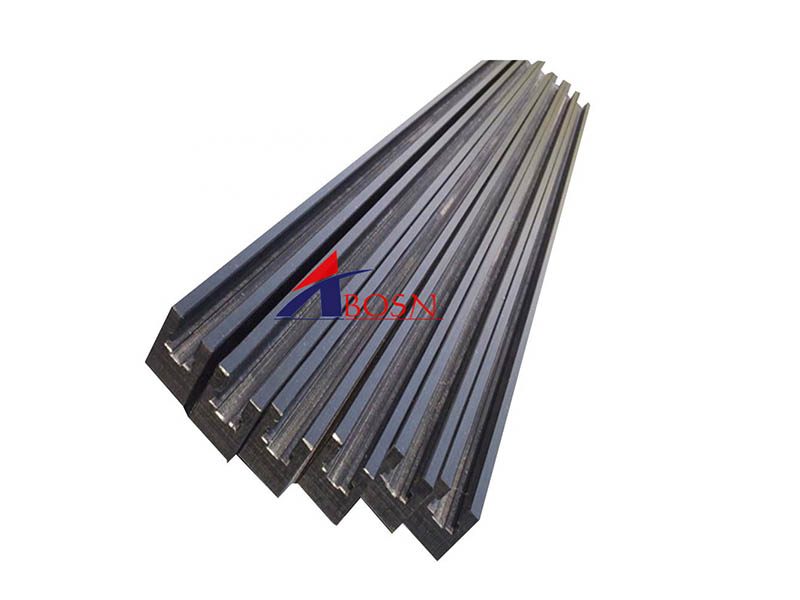

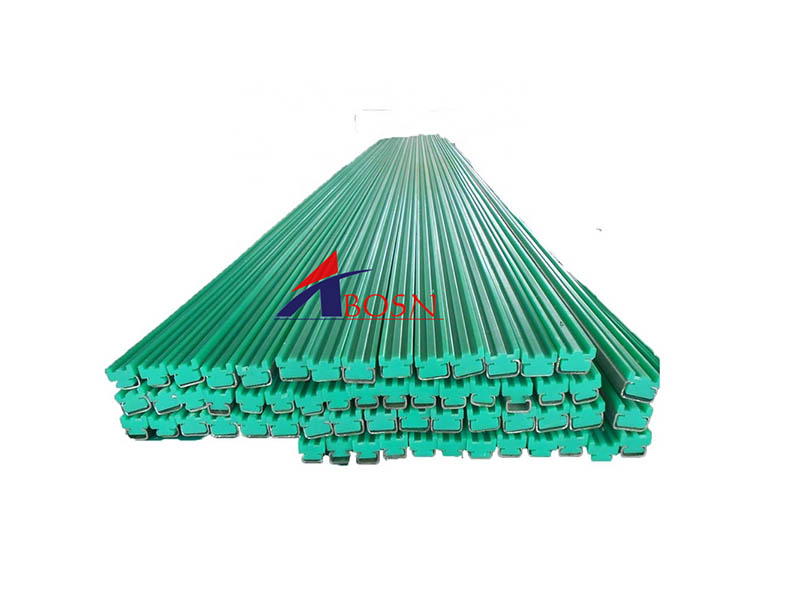

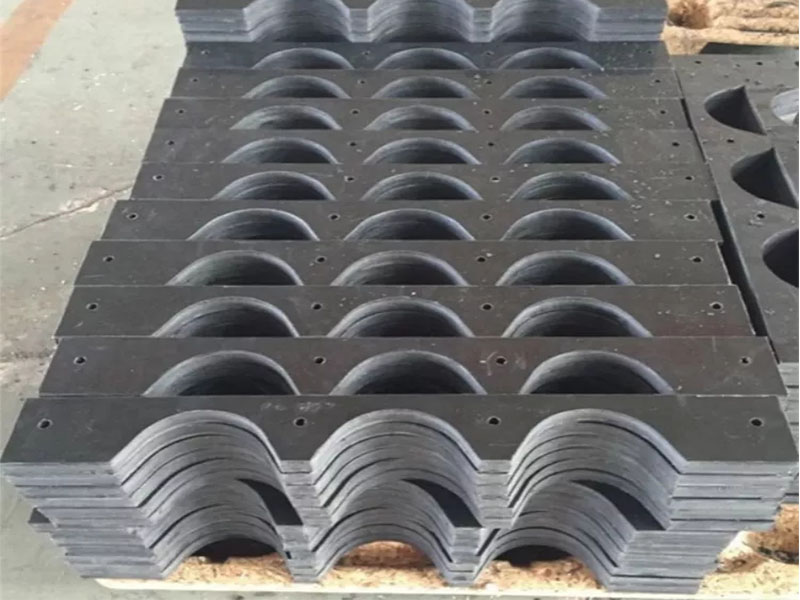

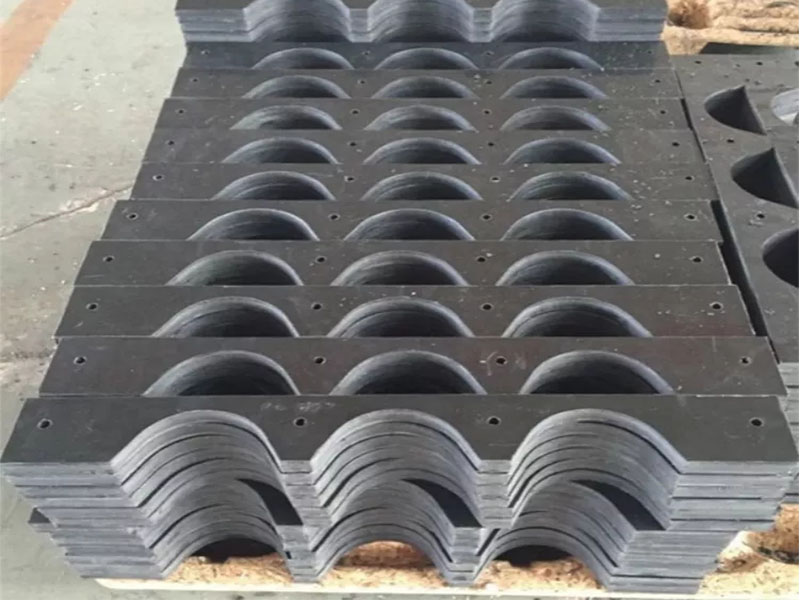

Black wear strip with CNC process

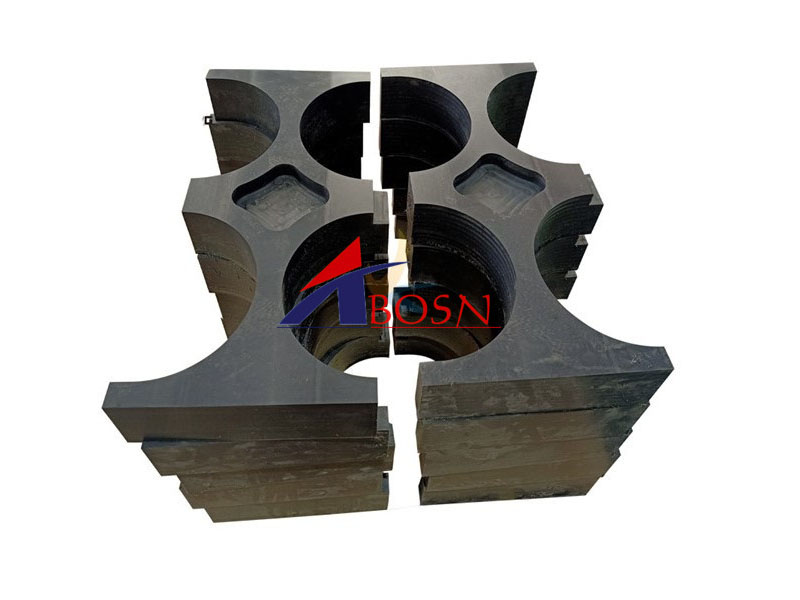

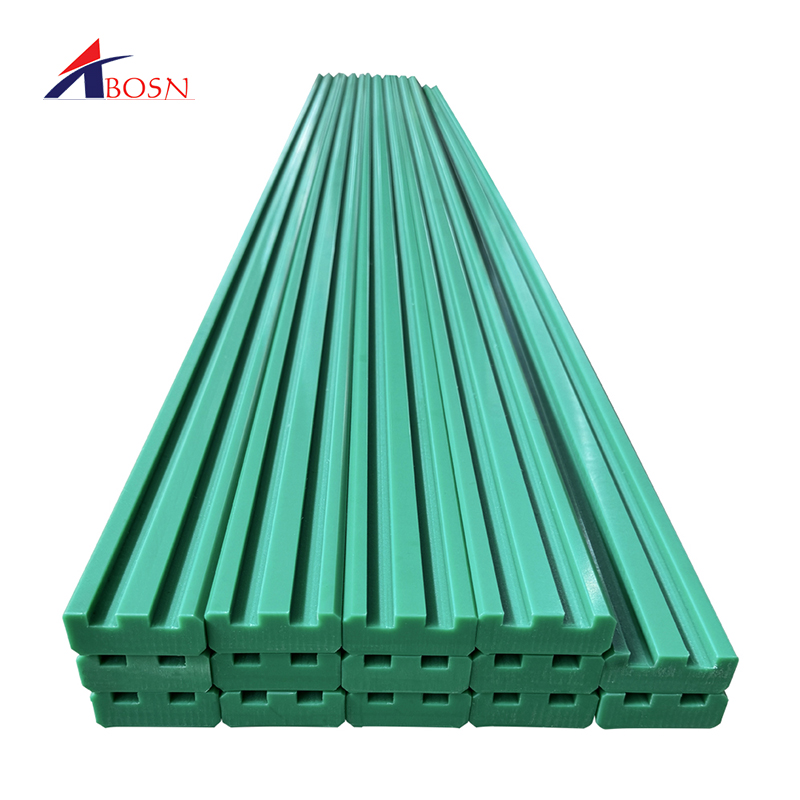

High chemical resistance, fatigue resistance, noise damping resistance, radiation resistance. Use temperature 100--110 ℃. It has outstanding impact resistance, resistance to stress cracking, high temperature creep resistance, low coefficient of friction, self-lubricating. Can use at -269 ℃. Density 0.985g / cm3 molecular weight of 2,000,000 of product, its tensile strength of 40MPa crack crack elongation of 350%, the elastic modulus of 600MPa tortuous Izod notched impact punch continued. The amount of wear (MPC method) 20mm.

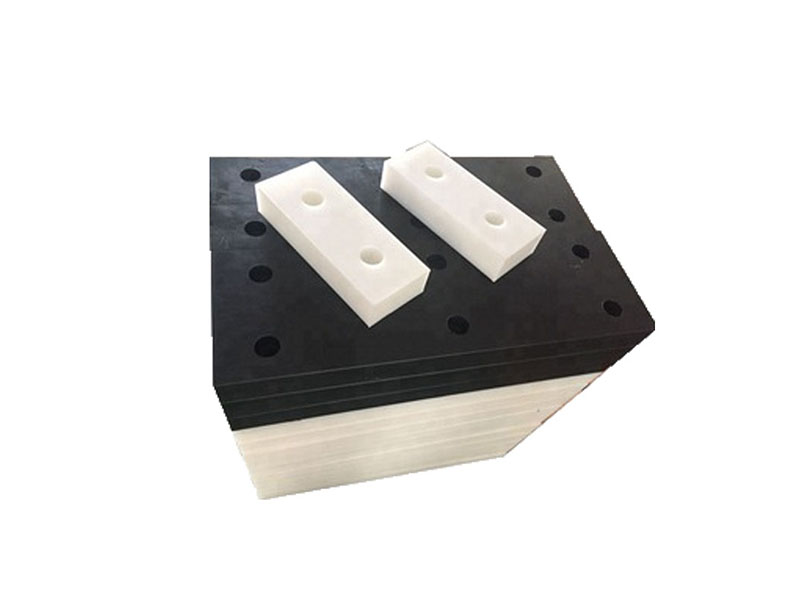

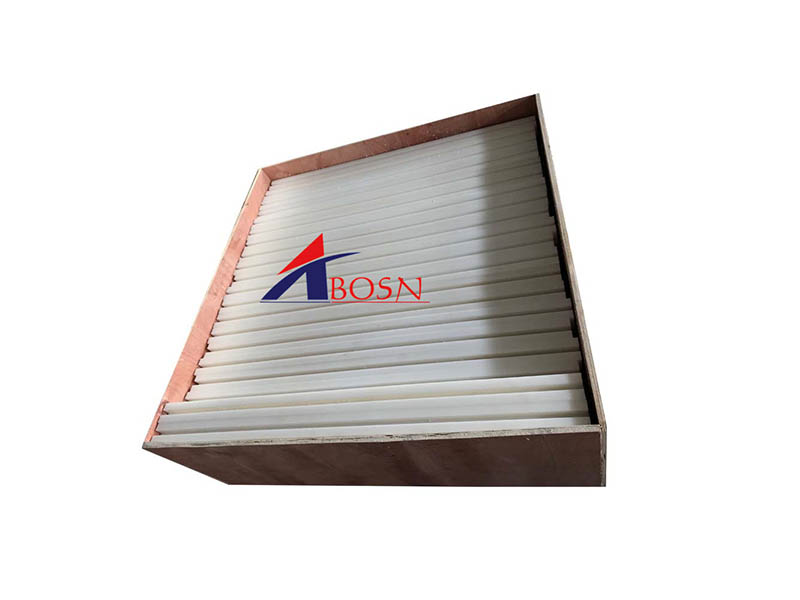

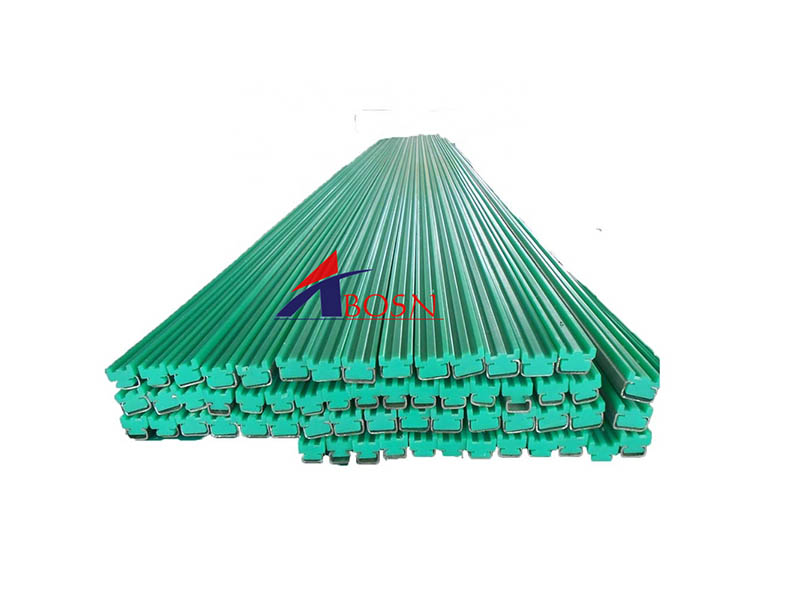

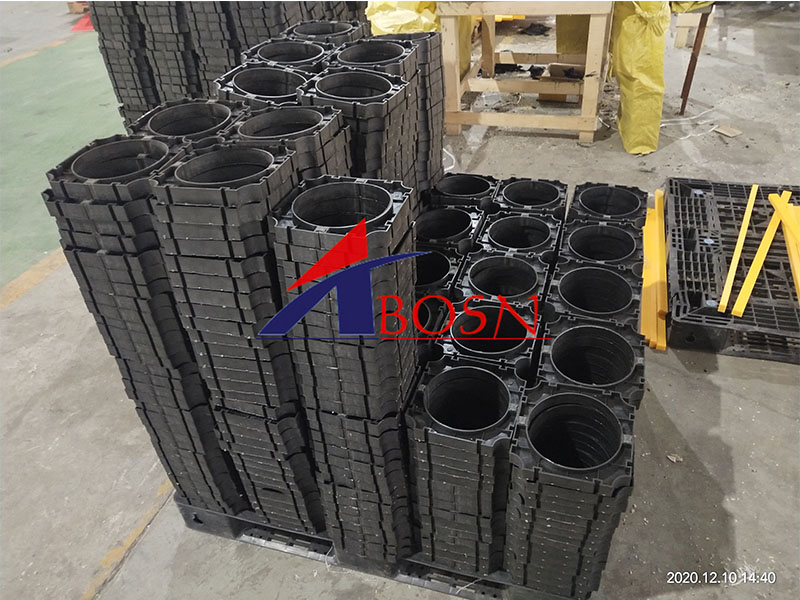

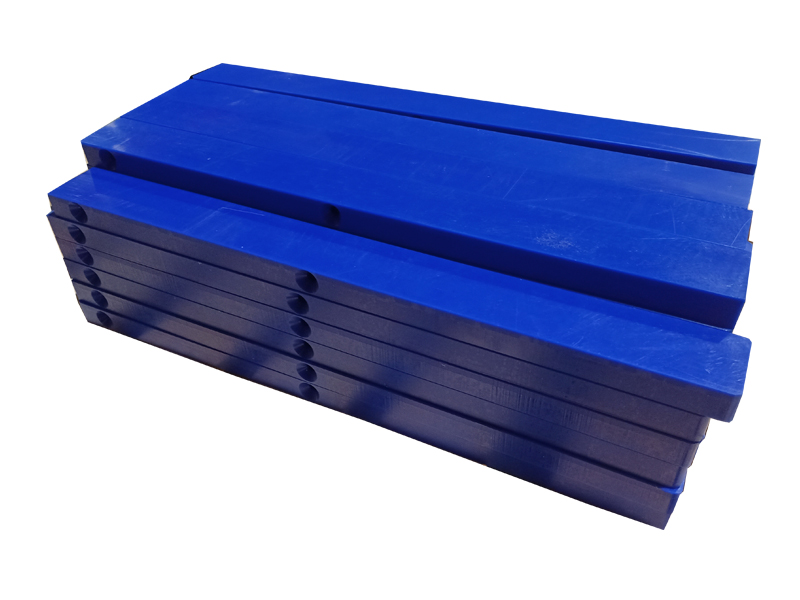

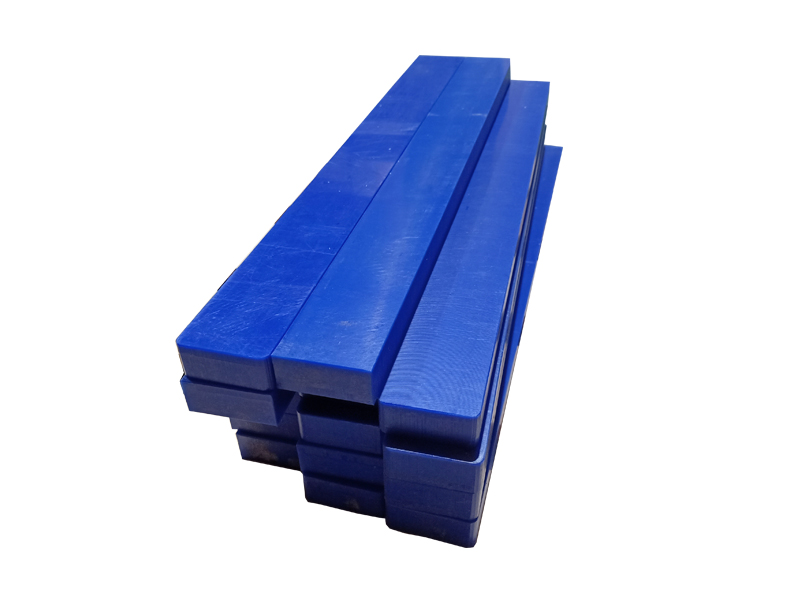

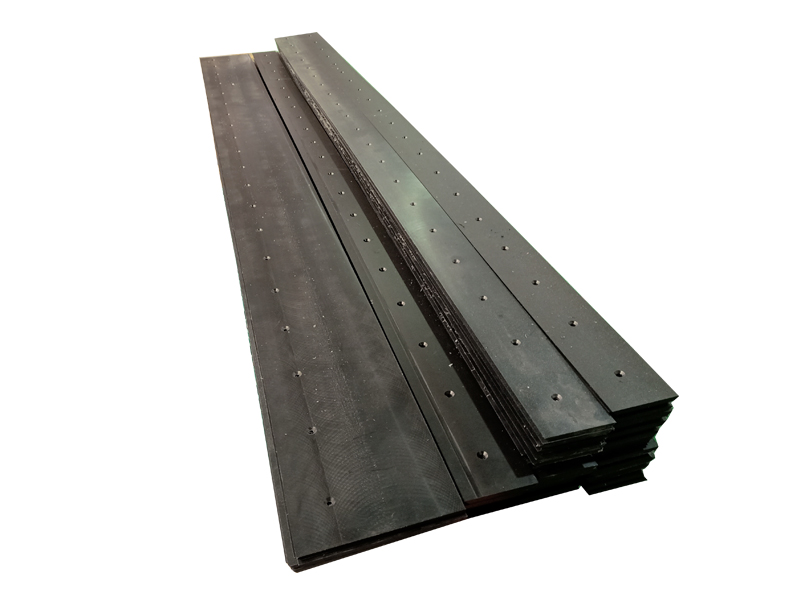

UHMWPE wear stirp features:

No moving parts, no lubrication ; hence zero maintenance

Extremely low coefficient of friction

High Abrasion resistant

Shock absorbing

No belt sagging, no belt mistracking

Protect belt from tear and puncture

Reduces spillage

Friendly with the side skirt sealing system as it eliminates the gap which occurs commonly between two conventional impact idlers

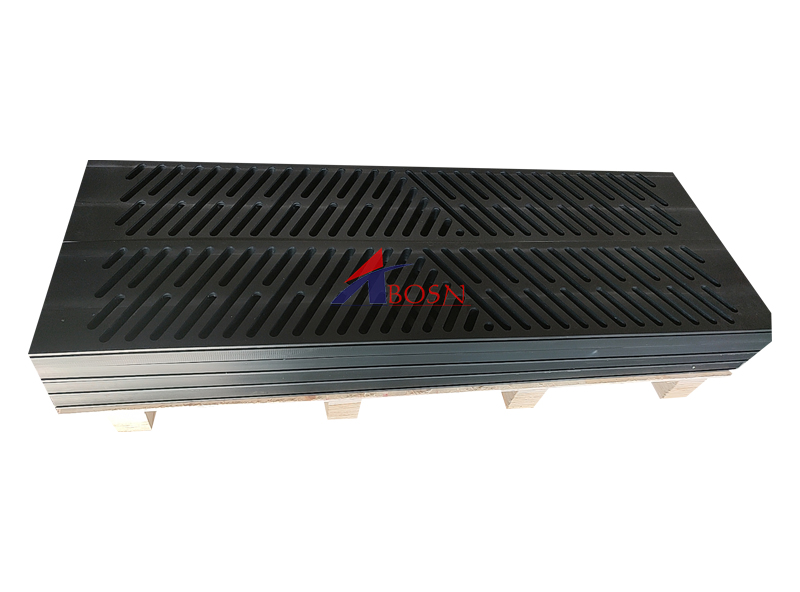

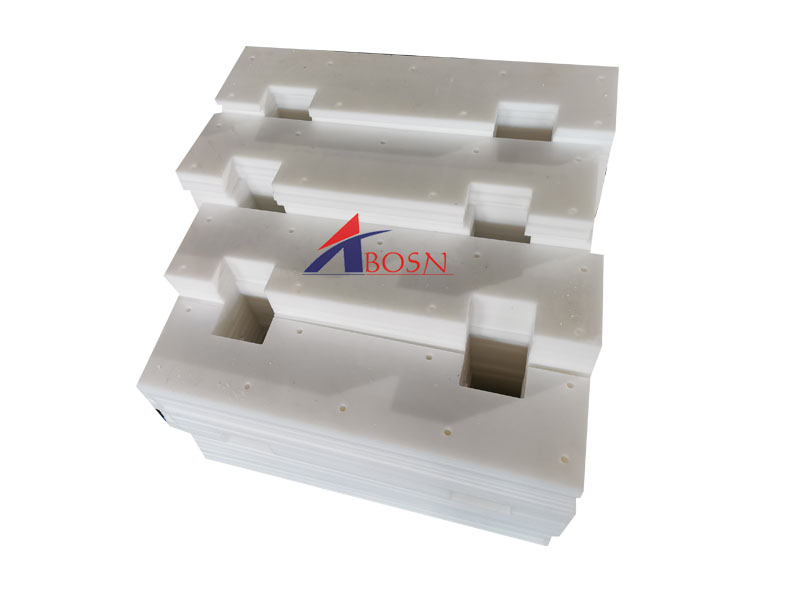

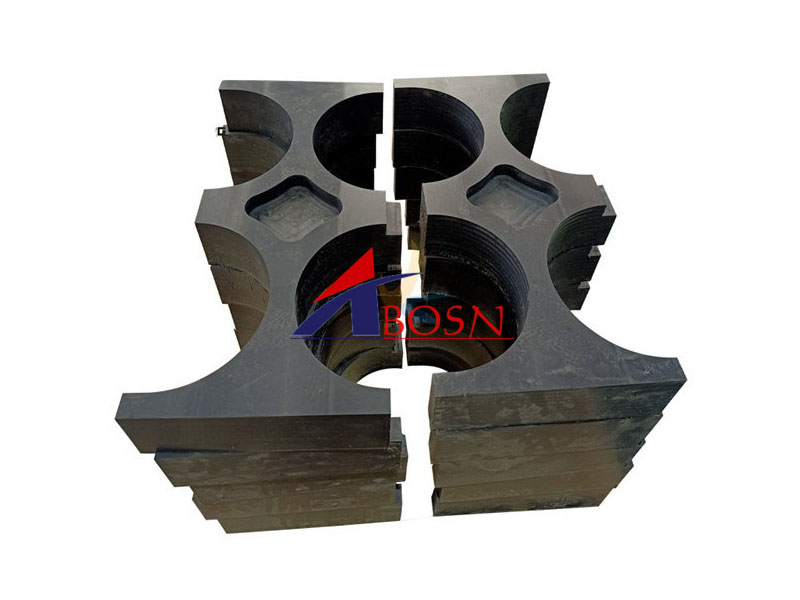

UHMWPE wear resistant strip Applications

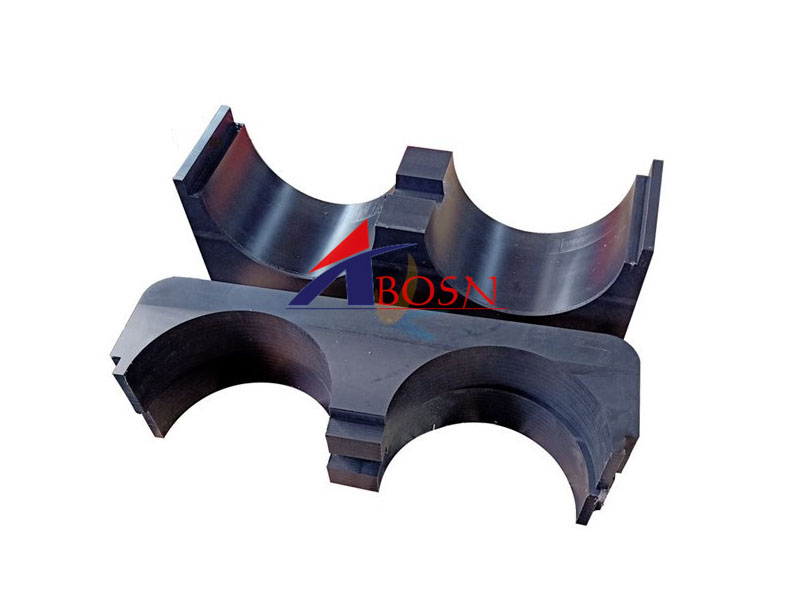

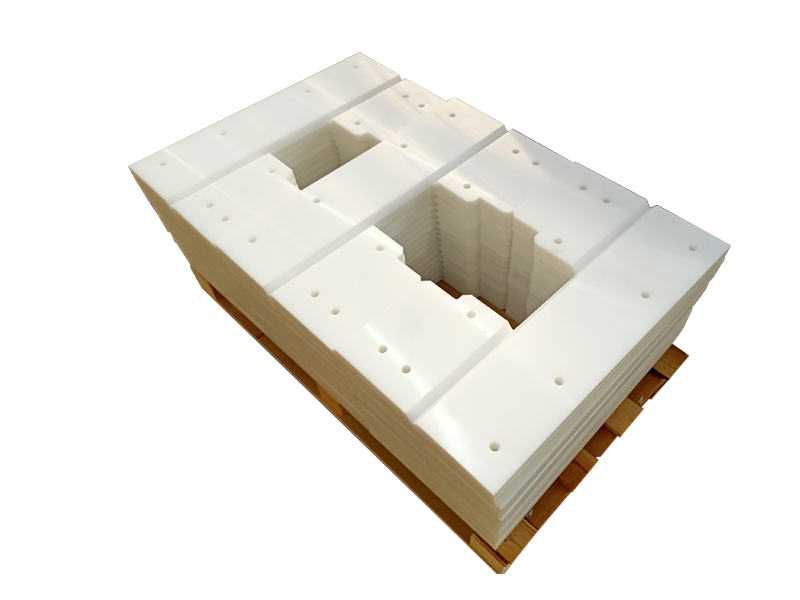

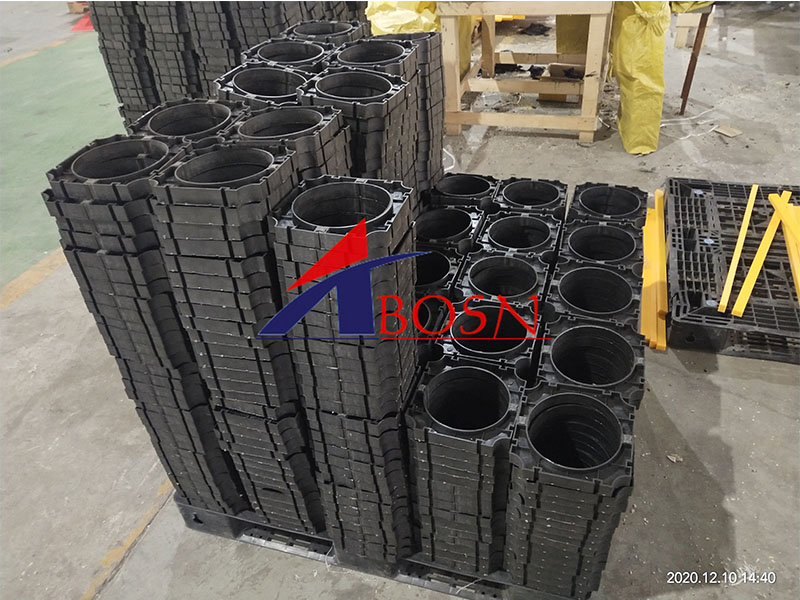

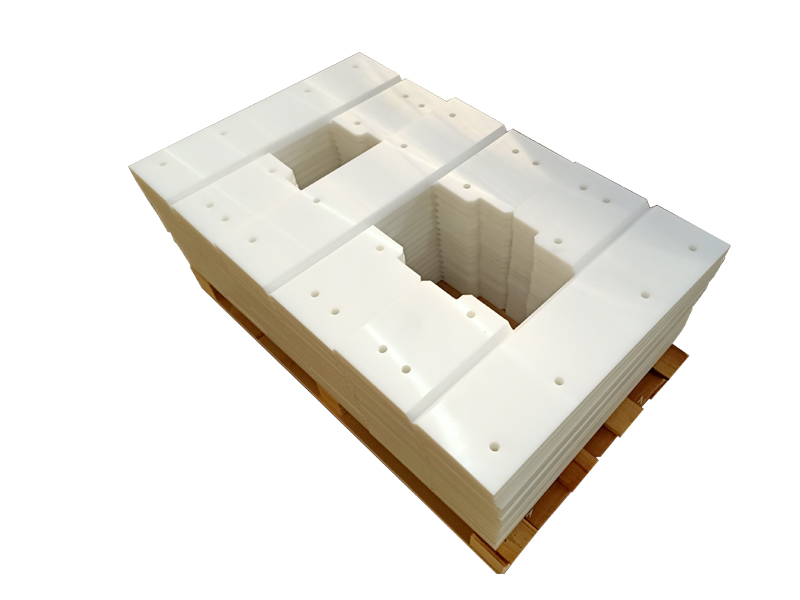

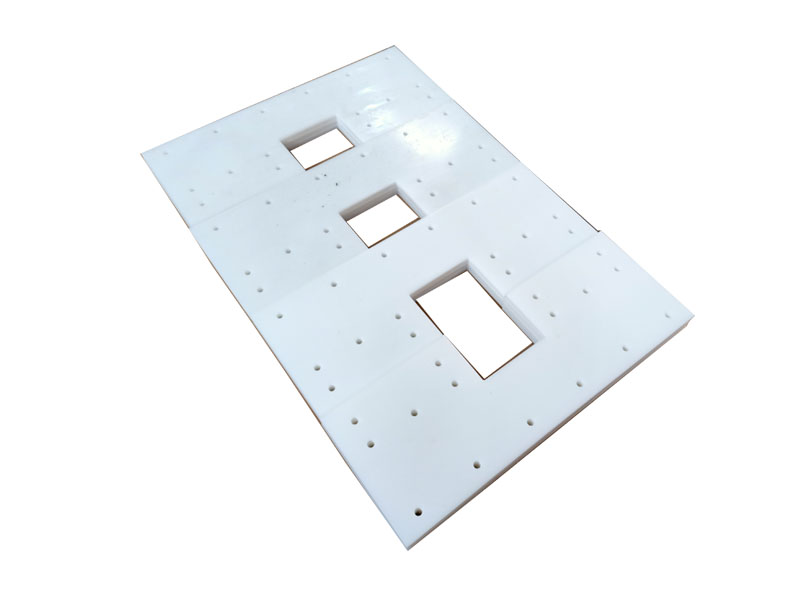

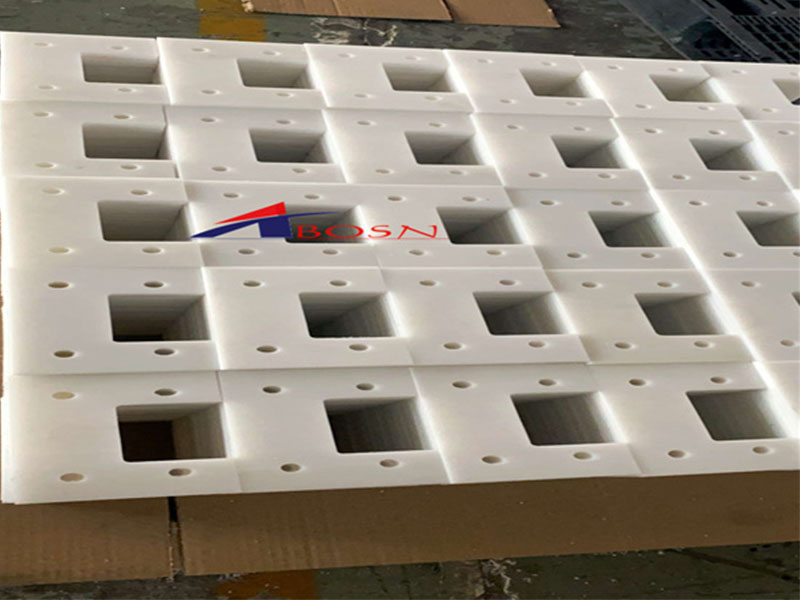

1,Used as lining board for bunker,chute,mixer,warehouse etc selflubrication and wear resisting needed areas

2,Made into block,dock fender board etc special purpose and special shaped products.

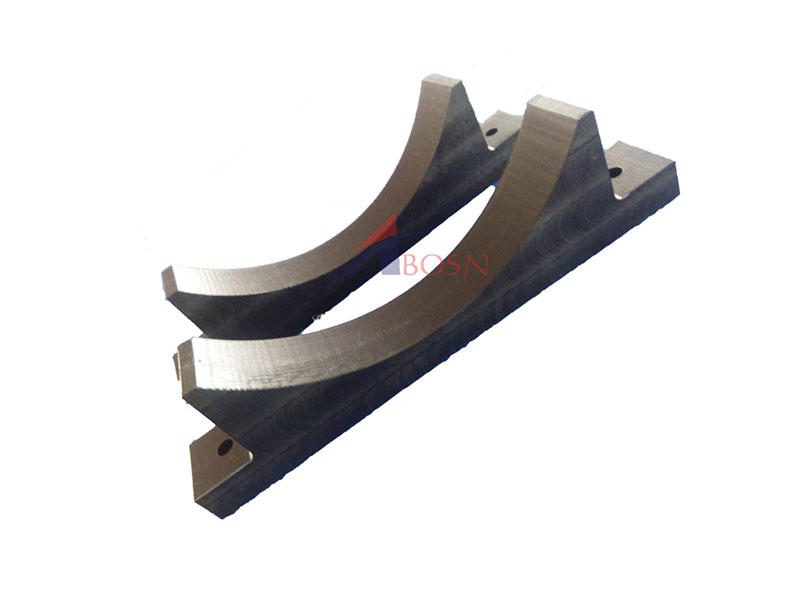

3,Made into all kinds of mechanical parts according to drawings under the help of lathe,mill machine and mould.

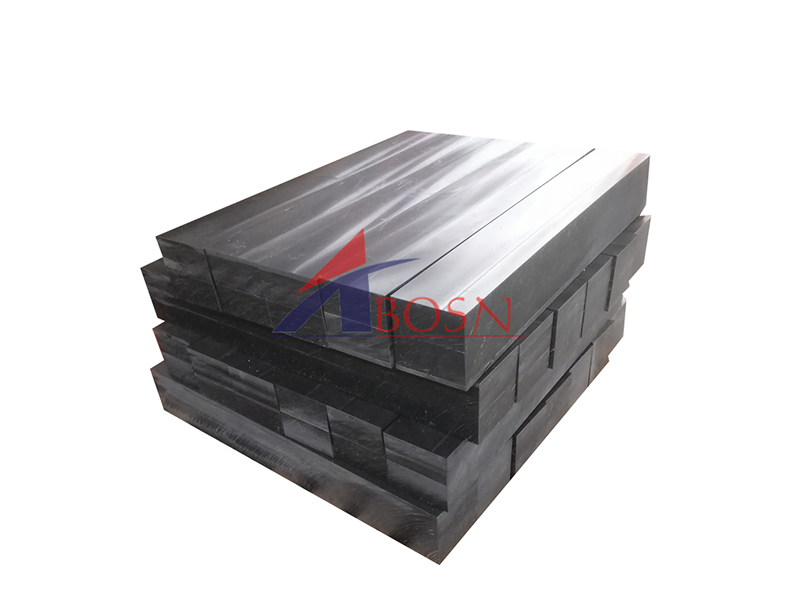

4,Due to the excellent property of high intensity and impact resisting,UHMWPE boards have been used in military include pallet for bulletproof jacket and bulletproof shield ,Protection level III and IV .

5,Other fields include Ice rink,water tank etc

If you want to some information,you can check our website https://abosnplastic.en.made-in-china.com/

Contact us

E-mail:fiona@dzabosn.com

Phone/Whatsapp:+86 175 5341 8926