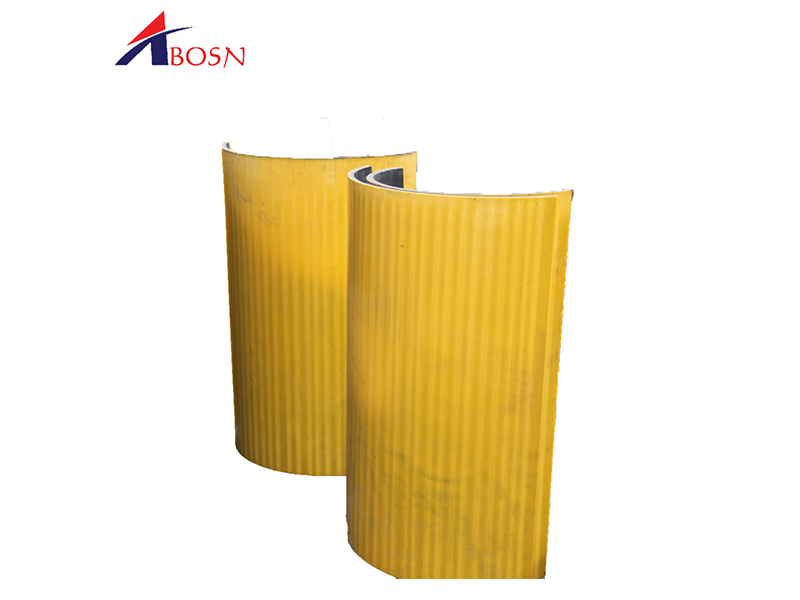

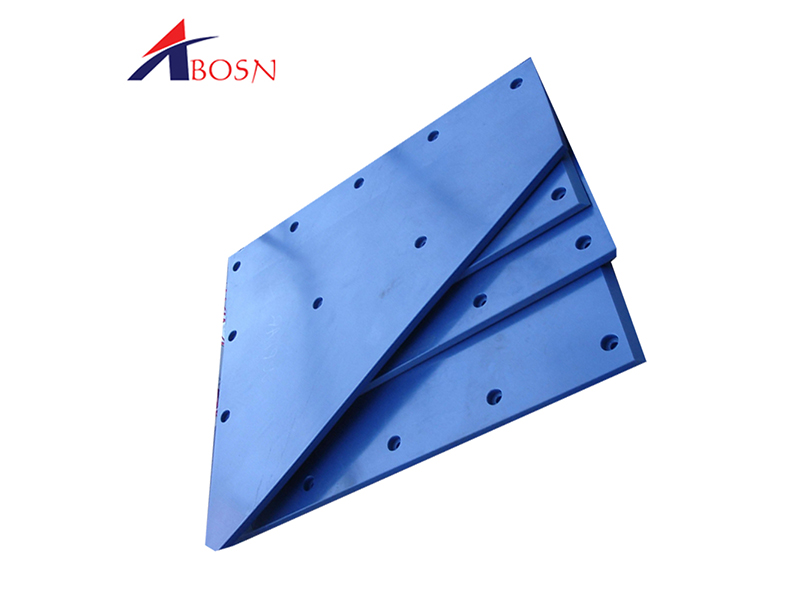

UHMWPE Coal Bed Chute Liners will help eliminate sticking problems. In the processing of bulk goods, equipment is often lined with a UHMW plastic material to promote the efficient flow of goods from one process or stage to the next. These liners for chutes, hoppers, silos, and industrial truck beds offer low friction and are abrasion and corrosion resistant, providing a long wear-life and reducing downtime in processing plants. They can be fastened to concrete, gunite, steel, and wood, making them both effective and versatile.

![]()

Product description:

1) ABOSN UHMWPE Liner sheet is a thermoplastic engineering material with high molecular weight and excellent performance.

2) ABOSN UHMWPE Liner sheet focused on the advantages of all kinds of plastic, which has incomparable wear resistance, impact resistance, self-lubrication, corrosion resistance, low temperature resistance, sanitary nontaxicity, extremely high smoothness and low water absorption.

3) In fact, there is no single polymer material has so many excellent properties like UHMWPE material.

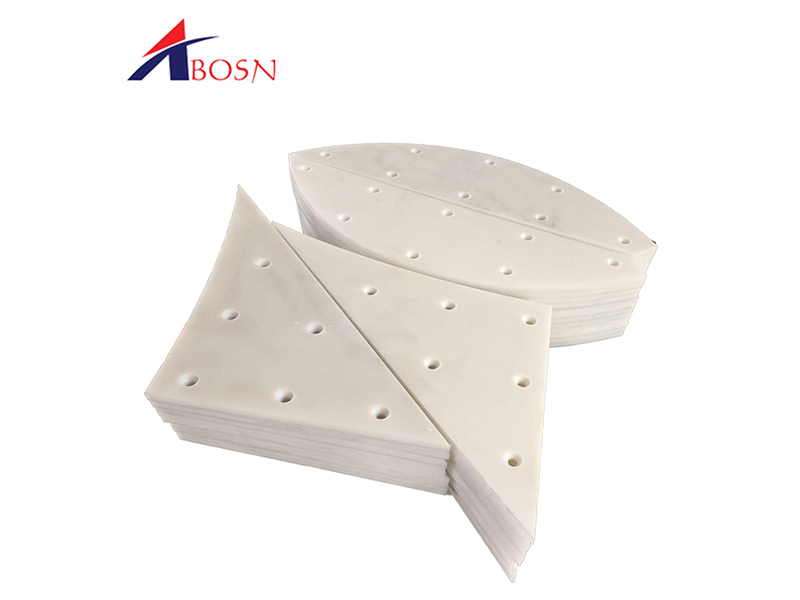

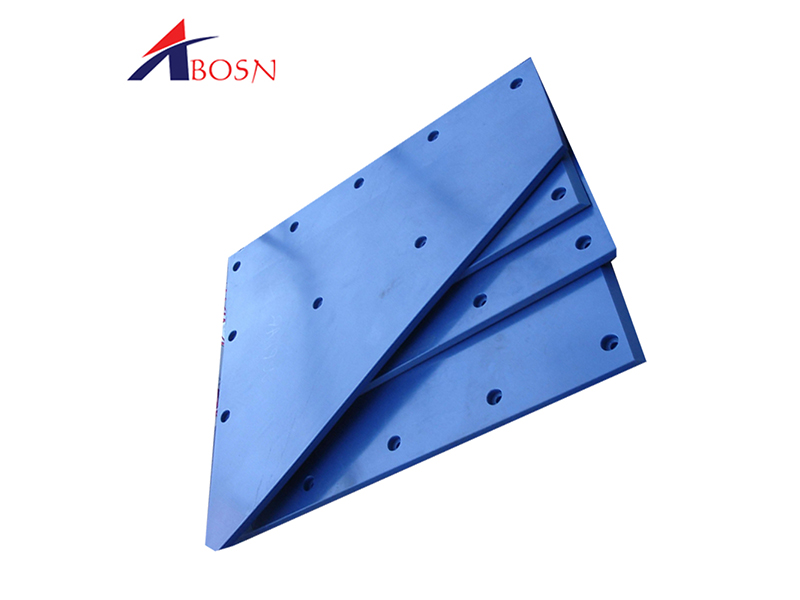

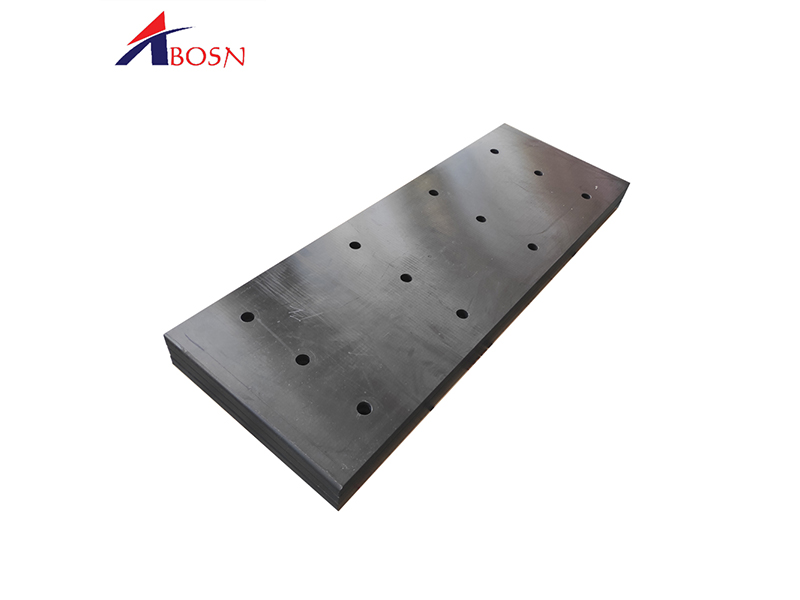

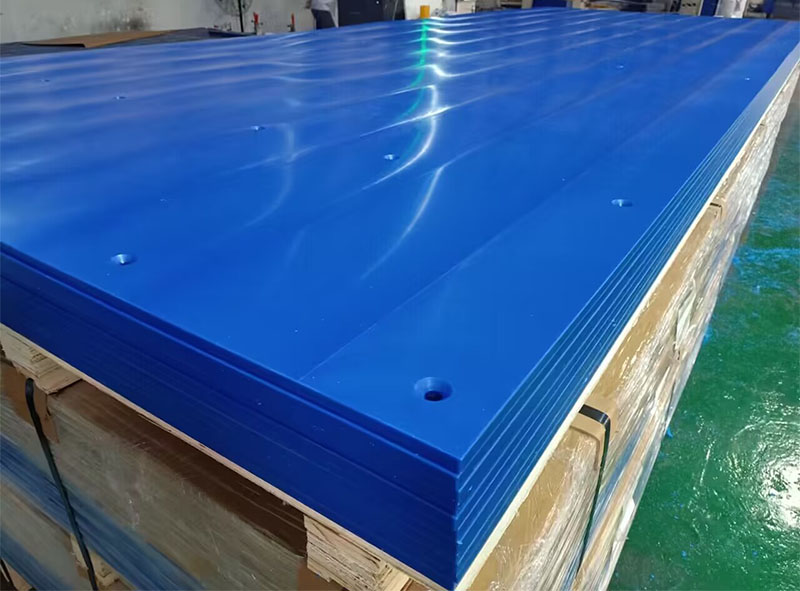

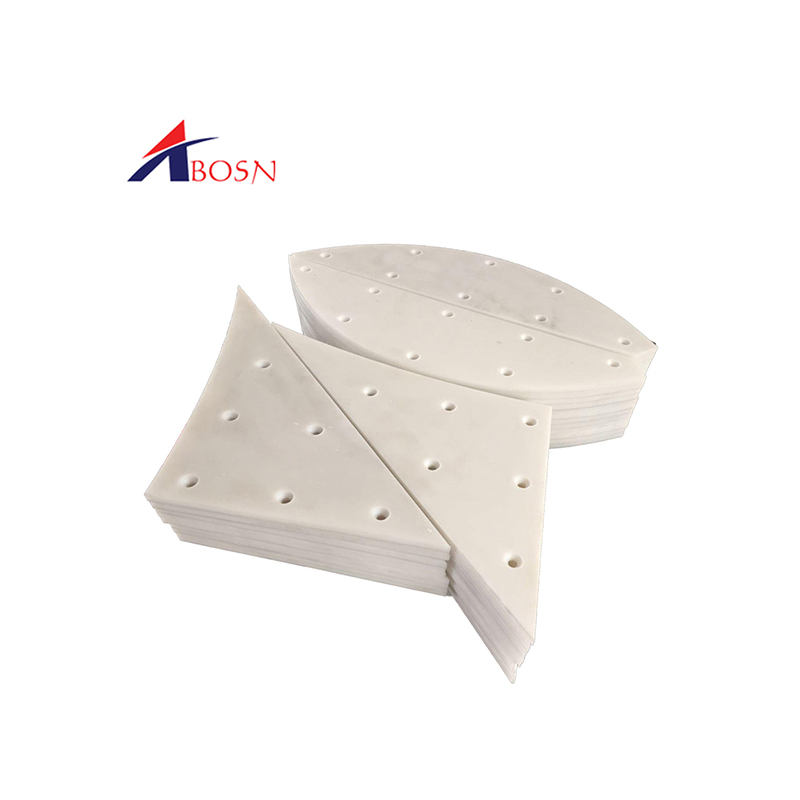

So, we provide UHMWPE liner in various shapes and sizes, which are available in different color such as Black, Grey, Natural, etc.

4) Our UHMWPE liner customized designs with distinct specifications in colors and dimensions.

5) UHMWPE lining sheets assist to reduce typical flow problems of bulk solids in bins, hoppers, chutes, truck beds and other applications. However, every application, brings with it unique challenges and places special demands on the plastic lining materials.

Product information:

| Property | Value |

| Density | 0.94~0.98 g/cm³ |

| Working temperature | -269~85℃ |

| Melting temperature | 130~160℃ |

| Elongation break | 350% |

| Tensile strength | 45.3MPa |

| Rockwell hardness | R57 |

| Bending strength | 23MPa |

| Compressive strength | ≥30 MPa |

| Impact strength | 100~160KJ/m³ |

| Charpy notched impact strength | ≥140 KJ/m² |

| Ball indentation hardness | ≥40 N/mm² |

| Heat conductivity | 0.14~0.16%(m/m) |

| Water absorption | ≤0.01% |

Key properties of UHMWPE liner, coal bunker liner:

· No incrustatons of bulkmaterial

· No bridging caused in hoppers

· Enhanced protection of plan tand machinery against wear

· Faster bulk material flow

· Costo flining exist hopper with PE1000 is one third of the cost of mild steel

· PE-UHMW is half the weight of steel, despite being three times as thick

Contact us

E-mail:fiona@dzabosn.com

Phone:+86 175 5341 8926

Whatsapp:+86 175 5341 8926